Recognising the need for a faster and more repeatable solution, Bowers Group turned to the Baty Venture FV 2020.

Recognising the need for a faster and more repeatable solution, Bowers Group turned to the Baty Venture FV 2020.

As a trusted supplier of precision metrology instruments, Bowers Group continues to invest in innovation to maintain the highest standards of accuracy, especially for its renowned range of British-made bore gauges.

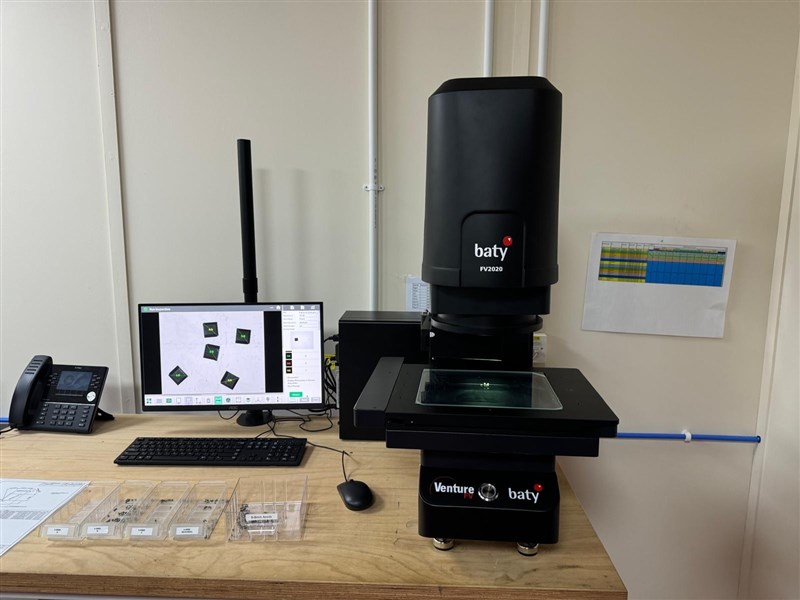

Recognising the need for a faster and more repeatable solution, Bowers Group turned to the Baty Venture FV 2020, a fully automated, non-contact vision measurement system, to streamline the process.

“The Baty Venture FV 2020 has taken the guesswork out of the process,” said Declan Hargreaves, CNC Grinding Technician at Bowers Group. “Once it’s programmed, anyone in the factory can run it and get the same result — accurate, every time. It’s a perfect example of using modern metrology to improve the way we produce a time-honoured product.

Manufactured at the company’s Bradford facility, Bowers’ XT3 range of digital internal micrometers and associated anvils form a critical part of the group’s measurement offering. These micrometers are engineered to measure internal features such as threads, splines, grooves, and dovetails with utmost precision. To maintain these standards, Bowers identified the need to evolve its internal processes and reduce variability in anvil production.

Historically, the anvil inspection process relied heavily on manual assembly and fit testing using rings and technician expertise to check dip and collapse. Although accurate, this traditional method was time-consuming and vulnerable to human error, often requiring multiple adjustments to achieve the desired fit.

The introduction of the Venture FV 2020 has transformed the way Bowers inspects its anvil components. Using high-resolution vision technology, the system enables batch measurement of multiple anvils at once, slashing inspection times from 90 minutes to just 20. By placing the anvil on the system’s precision stage, operators can instantly group components into tolerance bands, ensuring a consistent, accurate fit into the micrometer body with minimal effort.

Now used daily on-site, the Venture FV not only boosts throughput but also maintains strict quality control across production. Its intuitive interface and automated measurement capabilities have made it simple for any team member to operate, ensuring repeatable results without relying on specialist skills.

By pairing traditional craftsmanship with innovative vision systems, Bowers Group is reinforcing its leadership in bore gauging with a measurement process that’s just as precise as the tools themselves.

As the metrology world celebrates continued progress and innovation, Bowers Group remains committed to providing practical, high-performance solutions for manufacturers, ensuring every bore gauge that leaves its Bradford site is a testament to quality, reliability, and British engineering.

(84) 896 555 247