The BRAND NEW DP-I module is calibrated to the sensor, not the cable, enabling easy replacement and relocation without recalibration, even with cable lengths up to 10 meters.

Gauge probe technology is a vital component of the automotive manufacturing process. It’s integral to the delivery of a higher standard of parts, better-performing products, greater safety and stronger brand reputations.

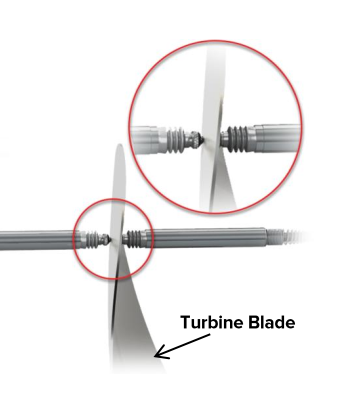

Specialists in the investment casting and machining of alloy metals, such as aluminium and titanium, which are primarily used for jet aircraft engines and airframes, have to measure the dimensions of the blades after surface grinding.

Specialists in the investment casting and machining of alloy metals, such as aluminium and titanium, which are primarily used for jet aircraft engines and airframes, have to measure the dimensions of the blades after surface grinding.

The standard DP range of Digital Spring Push Probes has justifiably become the work horse of the gauging industry. Very high resolution, excellent linearity and high data speed come as standard. Long life precision bearings, and an IP65 rating ensure that probes maintain their performance for millions of cycles.

Range: 3 to 2Omm — Accuracy: Up to 0.05% of reading — Resolution: Up to 0.01 ym — Repeatability: Up to 0.1Ifi ym.

Specialists in the investment casting and machining of alloy metals, such as aluminium and titanium, which are primarily used for jet aircraft engines and airframes, have to measure the dimensions of the blades after surface grinding.

After casting, the turbine blades undergo surface grinding to complete the collaboration of surfaces. The dimensions of the blade post-grind then need to be accurately measured as the initial proportions from the casting will have changed slightly. A precision process application is required to conform to final specification requirements (dimensional accuracy and surface finish).

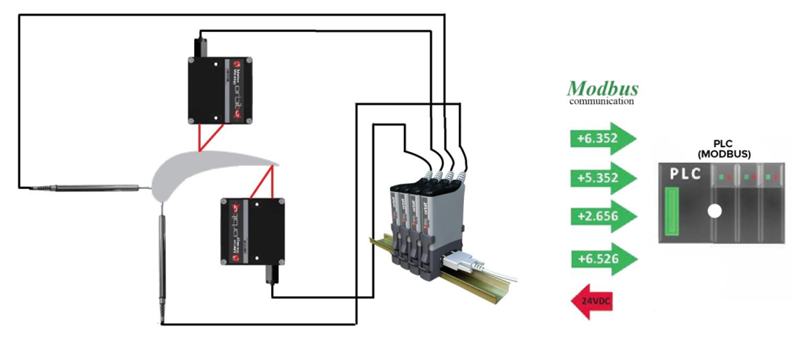

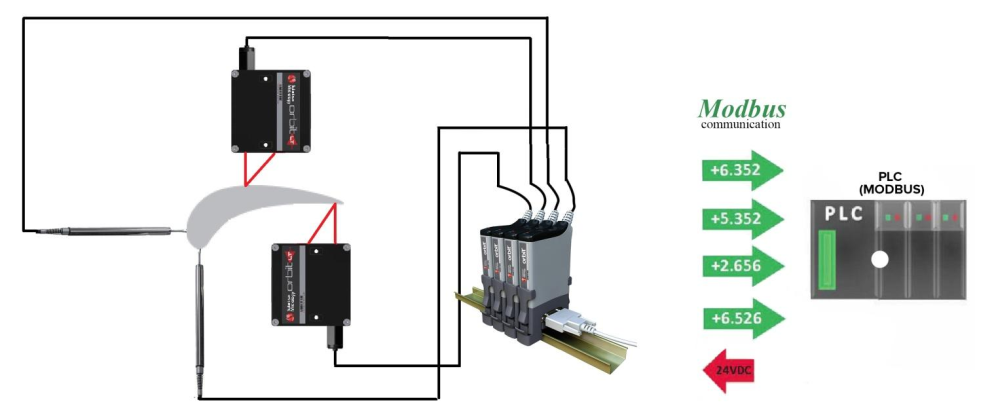

Using the Digital Spring Push Probes (DPs), the measurements from the desired locations on the turbine can be taken, and fed into the digital readout (SI5500). Measurement data from the SI5500 is transmitted via the unit’s RS232 output to a PC running a statistical process control system. This data is then used to monitor the performance of the grinding process and the quality of the finished parts, providing traceability records from the start of the process to the finished part.

(84) 896 555 247