Recent developments by Taylor Hobson deliver an in depth understanding of characteristics such as surface finish, contour, form, radius, roundness and harmonic analysis, providing vital feedback for improvements in design and production.

Recent developments by Taylor Hobson deliver an in depth understanding of characteristics such as surface finish, contour, form, radius, roundness and harmonic analysis, providing vital feedback for improvements in design and production.

Established in 1886, Taylor Hobson is the world leader in surface and form metrology and developed the first roundness and surface finish measuring instruments.

Taylor Hobson is part of the Ultra Precision Technologies Division of AMETEK, Inc. which is a leading global manufacturer of electronic instruments and electromechanical devices with 2014 sales of $4 billion.

AMETEK has over 15,000 colleagues at more than 120 manufacturing locations around the world. Supporting those operations are more than 100 sales and service locations across the United States and in 30 other countries around the world.

We provide contact and non-contact measurement solutions for the most demanding applications on a global basis, with a worldwide infrastructure to support our clients; we are a truly global ultra precision metrology company.

We are pioneers, continually developing our products to meet the ever-increasing demands of next generation technologies, particularly in optics, bearings, automotive, aerospace, medical and renewable energy technologies.

This forward thinking philosophy is captured perfectly in our diverse range of product solutions. Recent developments include new optics measurement systems and a full suite of dedicated software analysis packages.

Manufactured components require exceptional levels of quality, durability, precision and reliability in order to meet the demanding requirements of modern applications. Recent developments by Taylor Hobson deliver an in depth understanding of characteristics such as surface finish, contour, form, radius, roundness and harmonic analysis, providing vital feedback for improvements in design and production.

|

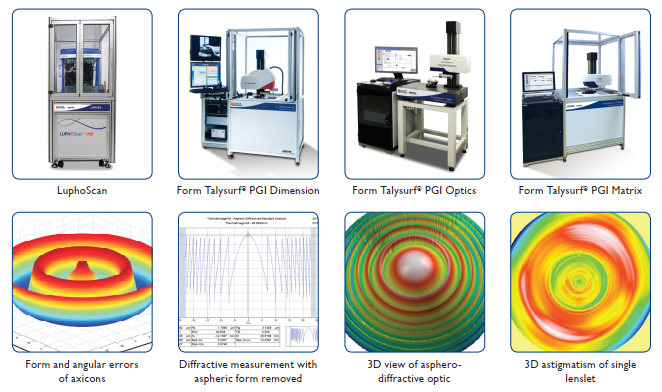

LuphoScan Ultra-precision non-contact 3D form measurement of aspheric surfaces based on MWLI® technology (multi-wavelength interferometry) • Up to 90° object slopes - ideal for measuring steep, small and large aspheres • Capable of measuring optics with a diameter of up to 420 mm • Full 3D form measurement of aspheres, spheres, flats and slight freeforms |

|

|

CCI Optics The large field of view and high resolution means the CCI Optics offers a wide range of measurement options for optics components • An extremely high resolution (0.1 ångström) measurement system • Unrivalled detail of turning marks - optimising surface finish • Full 3D, large data density delivers incredibly detailed analysis |

|

|

Form Talysurf® PGI Dimension Fully automated one-touch aspheric optics measurement, for 2D and 3D analysis of spheres, aspherics and diffractives up to 300 mm in diameter • Advanced software saves production time and increases output • Aspherics Analysis Utility (AAU) - save time and improve error detection • Measurement of virtually any part: steep, shallow, large and small |

|

|

Form Talysurf® PGI Matrix Designed to measure multiple parts, the PGI Matrix is a fully automated, fast and accurate system for precision measurement • Batch testing of multiple parts increases throughput • Easy set-up, test and analysis for single or multiple parts • Batches of parts, moulded lens and wafers can be analysed with ease |

|

|

Form Talysurf® PGI Optics With high instrument accuracy and versatility you are able to measure new and emerging designs, future-proofing investment • New gauge design with improved measurement range - up to 28 mm • Measure large sags - high accuracy and repeatability • Measurement of plastic lenses, small components, IR glass and crystals |

|

|

Latest developments and application solutions PGI Freeform, LuphoSharp, X-offset and tool tip radius errors • PGI Freeform - versatile, high resolution system for high precision freeform optics • LuphoSharp - highly accurate non-contact form measurement of acylindrical optics • X-offset - Unique solution for rapid machine tool set-up • Correlation, repeatability and traceability |

|

Source: Taylor Hobson

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

#taylorhobson #ametek #roughnessmeasuringmachine #surfaceprofiler #maydodonham #dodotron

(84) 896 555 247