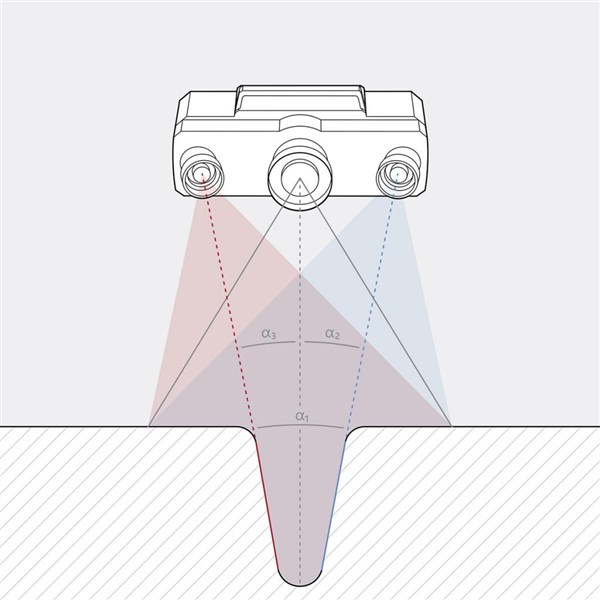

A 3D scanner is a device that collects data about the geometry (size, shape) and sometimes the color of an object, person, or surrounding environment. The output data of a 3D scanner is a set of X, Y, Z coordinate points called a point cloud, which is used to create a complete 3D model.

Dimensional measurement is how we know and quantify the size and shape of things. It involves lengths and angles as well as geometrical properties such as flatness and straightness. Dimensional measurement is of fundamental importance for interchangeability and global trade. It is how we ensure that things will fit together. Without global length standards as the basis for standardized parts globalized industry would not be possible.

From the dawn of man, there have been leaders. Even during prehistoric time, leaders walked the earth. Unlike the dinosaurs though, leaders did not become extinct.

How data is captured, processed and used is really what is smart about smart manufacturing.

Smart manufacturing is really all about data. It’s about collecting and using accurate data to make good decisions quickly to allow for slick, efficient and flexible manufacturing which can adapt to sudden changes in demand or circumstances. Heavily automated processes require a constant stream of data to make decisions and adjustments so that data has to come from accurate measurements using equipment which is flexible enough to still be useful if the process needs to change. Using machine learning algorithms, smart manufacturing operations can constantly improve and streamline their processes.

Gathering Data

How data is captured, processed and used is really what is smart about smart manufacturing. Data is gathered at every stage of every process so accurate metrology is vital. The data is monitored and analysed to make sure every part of the process is as efficient as possible and collecting all of this data together to look at the entire value chain enables identification of areas which can be streamlined. Having such a detailed and interconnected overview of the whole manufacturing process allows for adaptions to be made when changes take place.

Manufacturing Flexibility

With the current demand for customization and the need for manufacturers to be able to accommodate sudden changes in trends, smart manufacturing systems have to be flexible enough to change quickly. Using measuring devices which are as flexible and adaptable as the systems themselves allows for these changes to take place and the data they collect can be analysed to make sure the changes are having the desired effect or the new processes are as efficient as possible.

Efficiency Gains

Smart manufacturing and automation in general is all about efficiency but it is impossible to create ultra-efficient processes if the equipment you are using to collect the data that the whole system is so reliant on isn’t efficient or is difficult to integrate with other data-gathering equipment. Solartron’s sensors and probes are suitable for smart manufacturing because they’re highly accurate, efficient and easy to operate. Using the Orbit Digital Measurement Network, Solartron’s sensors and others can be used together to produce meaningful and easy to access data.

Process Visibility

It isn’t all about machines using this data, however. The constant monitoring and analysing at every stage of the manufacturing process gives operators great insights into what is really happening during each process and gets to the root causes of problems in real time. By allowing workers to see exactly what is going on at each stage and reporting it live to an easily accessible device, managers can make decisions instantly based on reliable data.

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

(84) 896 555 247