Vietnam currently has over 1,000 mobile app publishers, of which the proportion of revenue from foreign markets is increasing.

Read more

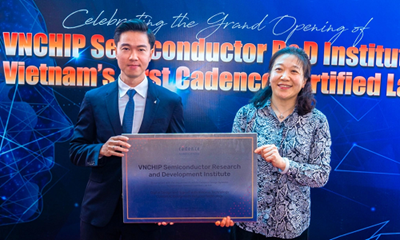

VNChip Institute for Research and Development of Semiconductor Technology and Cadence Design Systems (U.S.) signed an agreement to train high-quality microchip personnel in Vietnam.

Read more

A representative from TikTok Vietnam stated that the platform will process movie recap videos within 48 hours after receiving a copyright infringement report.

Read more

Gold is used to make jewelry, and not only that, it is also a form of currency. Societies and economies have long recognized and maintained the value of this precious metal. Why are people attracted to gold and not platinum, silver, or any rock in your backyard?

Read more

Apple Maps has started supporting real-time navigation when an iPhone is connected to a CarPlay-equipped car in the Vietnamese market.

Read more

China dominates with its ability to produce humanoid robots at a large scale, low cost, and quickly train and deploy them for practical use.

Read more(84) 896 555 247