SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

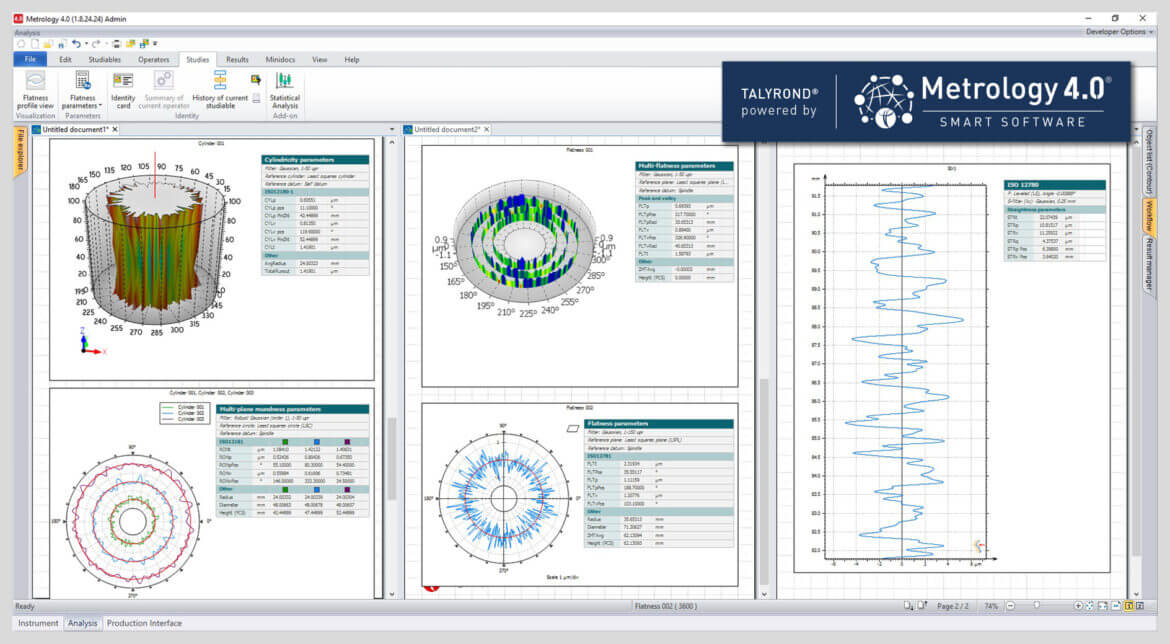

Following recent co-developments with Digital Surf, the software now also allows both measurement and analysis on the Taylor Hobson roundness instrument series.

Digital Surf and Taylor Hobson, world leader in surface and form metrology, have a common history dating back almost 30 years. The two companies recently completed a new round of co-developments resulting in the release of an updated version of Metrology 4.0 software with the manufacturer’s brand new Talyrond® 500 PRO, a powerful instrument for roundness metrology.

WHAT IS METROLOGY 4.0 SOFTWARE?

Metrology 4.0 software made its debut in 2018 with the Form Talysurf® PGI NOVUS series of surface instruments. Following recent co-developments with Digital Surf, the software now also allows both measurement and analysis on the Taylor Hobson roundness instrument series.

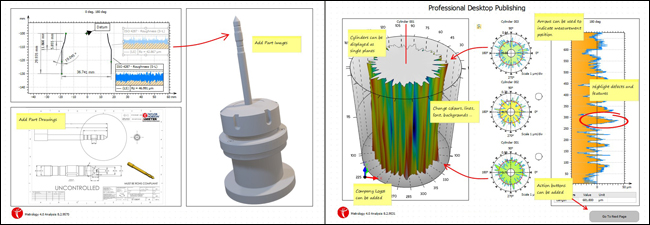

Mountains® platform software features are seamlessly integrated into Metrology 4.0, which allows better control of the measurement process and the direct creation and export of analysis documents.

This full integration offers several clear advantages. Users working with roundness can now benefit from a fluidified and optimized workflow, with the ability to progress from measurement to reporting within the same interface, making the metrology process much simpler and more straightforward. This is particularly useful in a production context (shop floor use).

BRINGING TOGETHER THE EXPERIENCE OF INSTRUMENT & SOFTWARE EXPERTS

“Cooperation between Digital Surf and Taylor Hobson goes back almost 30 years” said François Blateyron, director of research & metrology at Digital Surf. “Both teams understand each other. Our development department was able to build on its robust scientific knowledge to adapt to the new challenges of roundness metrology in the context of this project.”

“Our combined experience in the field of precision roundness measurement and in-depth analysis software provides unique benefits.” said Jon Gardiner, senior business development manager at Taylor Hobson. “Together we have produced the seamless integration of mechanical hardware and roundness metrology analysis software to deliver a world-class measurement instrument.”

TALYROND® 500 PRO - ROUNDNESS, PROFILE AND SURFACE FINISH ON A SINGLE PLATFORM

The Talyrond® 500 PRO is unsurpassed in speed and position control making it the ideal system for high volume precision components. Critical to any measuring instrument is the stability of its metrology frame, Taylor Hobson’s expertise is in producing extremely low noise, high resolution instrumentation that guarantees measurement integrity.

Applications

- Bearing Races, Roller Bearings & Ball Bearings

- Ball and Lead Screws

- Fuel Injectors

- Turbochargers

- Crankshafts & Camshafts

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

(84) 896 555 247