SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

The newly launched Nimbletrack Gen 2

SCANOLOGY has just introduced the NimbleTrack Gen2, the next generation of its mobile optical tracking and 3D scanning system. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy.

A highlight of SCANOLOGY's NimbleTrack Gen2 is its ability to measure large objects without moving the device. This is especially important in industries such as automotive and aerospace.

Renishaw is the principal advisor for the DECSAM project.

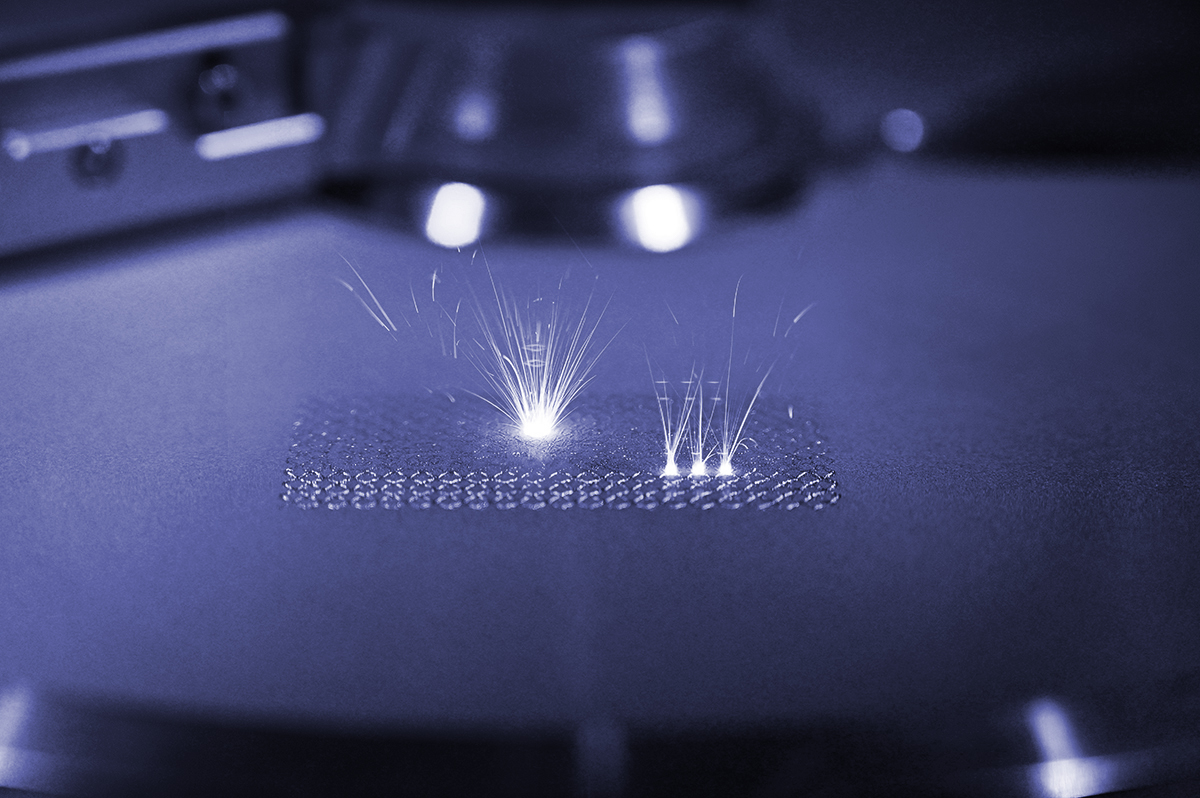

Renishaw has just announced its participation in the £38 million DECSAM (Digitally Enabled Competitive and Sustainable Additive Manufacturing) program. This program focuses on scaling Additive Manufacturing (AM) technology for the UK aerospace industry, aiming for greater sustainability and competitiveness. Renishaw will play a key role, sharing expertise on metal Additive Manufacturing systems, particularly post-processing and quality control technologies.

Renishaw's primary goal in participating in DECSAM is to reduce the cost and time required to bring highly complex AM components into use in the aerospace industry. Renishaw will assist in researching new materials, processes, and software. Renishaw hopes the program will accelerate the application of Additive Manufacturing in the production of aircraft engines and wings.

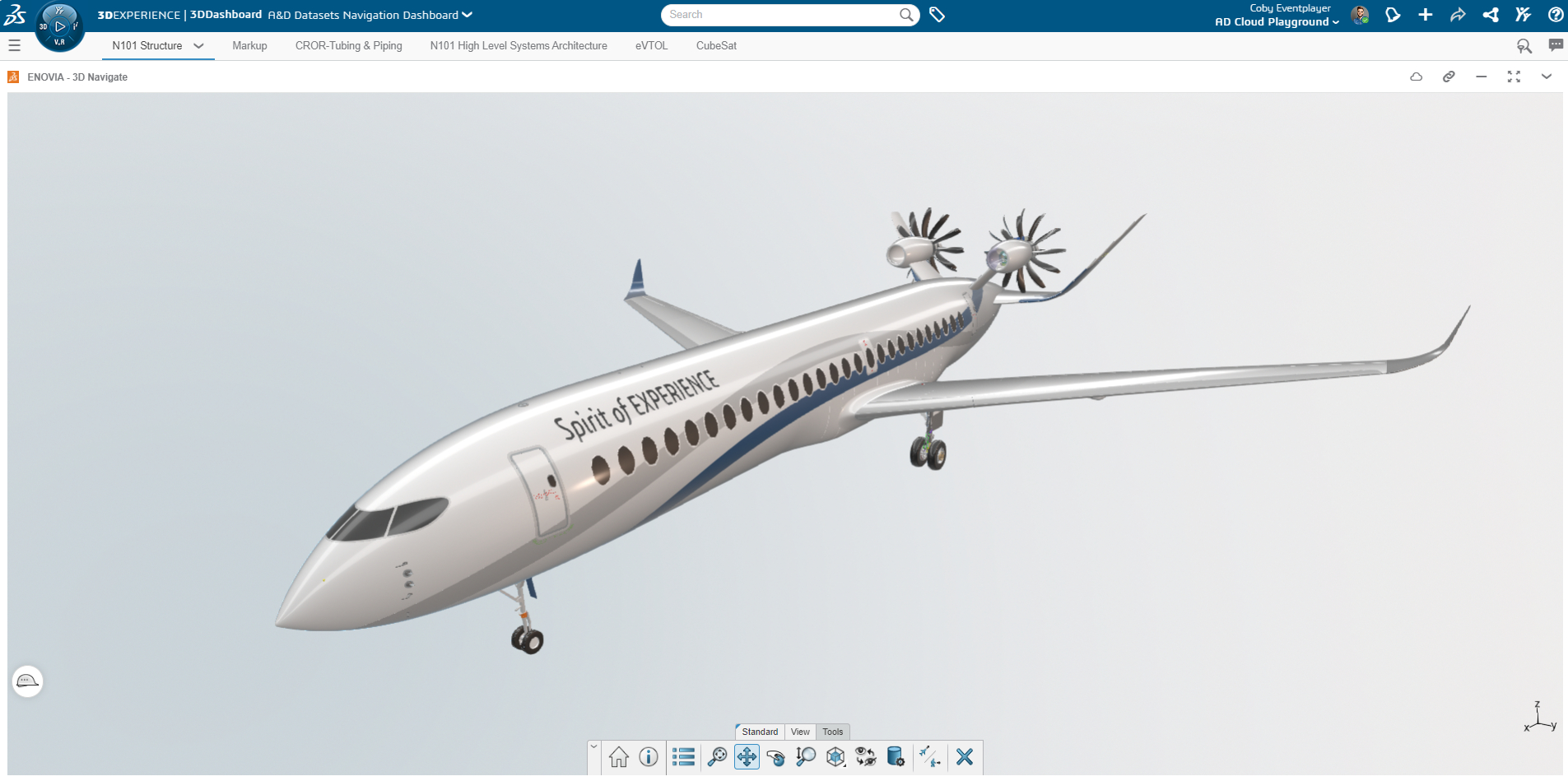

Renishaw is now available on Dassault Systèmes' 3DEXPERIENCE platform.

Renishaw's Additive Manufacturing System is now deeply integrated into Dassault Systèmes' 3DEXPERIENCE platform. This integration provides users with a seamless digital workflow, from design to simulation and actual production. Users can directly access and utilize the specifications of Renishaw's Additive Manufacturing System (including the RenAM 500S series) within the CATIA and SIMULIA software environments.

Integrating Renishaw's Additive Manufacturing System optimizes the design of AM parts, ensuring they are built correctly the first time. The 3DEXPERIENCE platform enables printing process simulation and deformation prediction, minimizing the risk of manufacturing errors. This collaboration expands access to Renishaw's leading metal AM solutions.

One of Scanology's International Certifications Received This Past Week

SCANOLOGY has achieved three important international certifications for its innovation management and R&D activities. These certifications include Innovation Management, R&D Management, and another related to technical innovation. Achieving these certifications affirms SCANOLOGY's commitment to developing high-quality 3D measurement technology and globally standardized R&D processes.

These certifications demonstrate that SCANOLOGY is not just a manufacturer of equipment, but also an organization with an effective innovation management system. This is a driving factor in the company's continued leadership in developing advanced 3D scanning products, such as the new NimbleTrack series.

Mahr's new factory in Wörth am Rhein focuses on serving customized customers

Mahr, a leading manufacturer of metrology equipment, has opened a new site in Wörth am Rhein, Germany. Mahr opened this new facility to focus on developing and manufacturing customized metrology solutions for customers. Mahr's decision to open a new facility reflects the growing demand for automated quality control systems, specifically designed to suit the unique production processes of each customer.

The Wörth site will serve as a Center of Excellence for complex, integrated measurement systems. Mahr's new facility allows it to respond more quickly to specialized requests, thereby strengthening its leading position in the industrial measurement market.

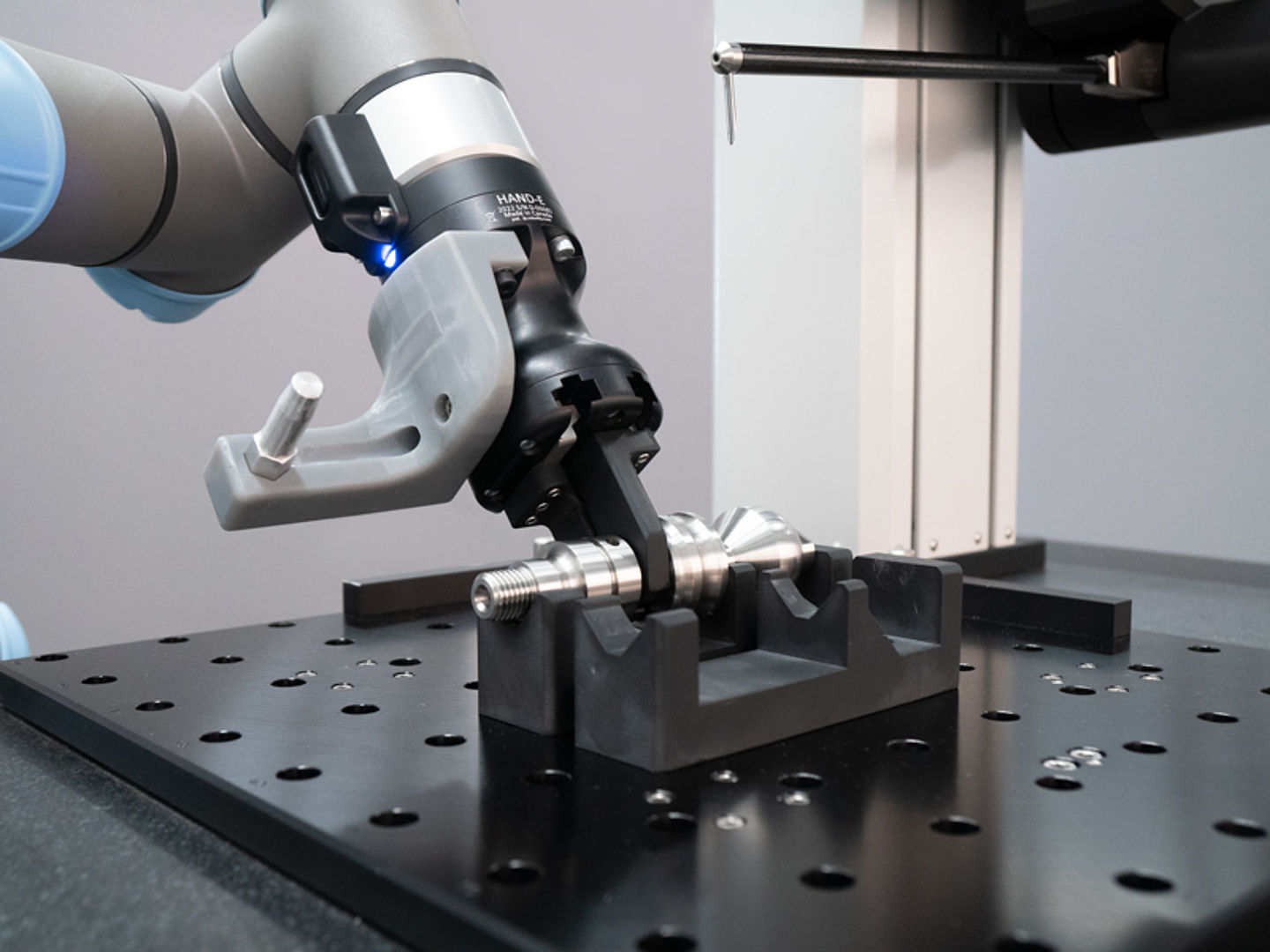

Mahr has upgraded its automated form measurement system, enabling flexible form measurement automation. This upgraded system addresses the challenge of inspecting complex and large-sized parts requiring high precision while maintaining a fast and automated process. This automated form measurement system is designed for easy integration into production lines.

The automated form measurement capability eliminates operator error and ensures repeatability of results. The system utilizes robots to change measuring heads and position parts, optimizing the batch inspection process for various components.

Update your knowledge on quality management through our training section at: https://v-proud.vn/en/news.htm

Read more:

(84) 896 555 247