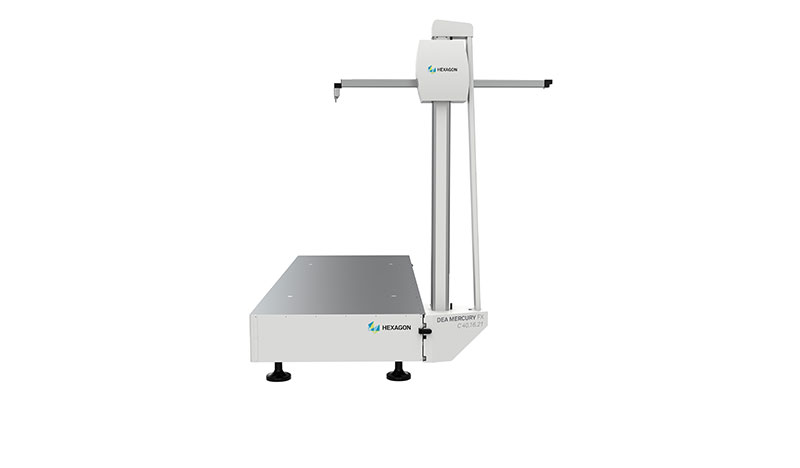

The DEA MERCURY FX is a horizontal arm coordinate measuring machine (CMM) upgrade solution that uses existing infrastructure to simplify the installation of the latest, productivity-enhancing measurement systems.

The DEA MERCURY FX is the ideal solution for horizontal arm users that want to leverage their current assets when adopting new measurement technologies. Designed to be fitted onto an existing horizontal arm CMM base table, even if it is a non-Hexagon system, the DEA MERCURY FX offers all the long-term performance advantages of a new CMM system, while minimising disruption to busy workplaces during installation.

The DEA MERCURY FX combines mechanical accuracy with high repeatability and its open architecture, robust mechanical frame and automatic axis motion make it ideal for loading and unloading even the heaviest medium, large and very large parts. Versatile, the DEA MERCURY FX offers a choice between using tactile sensors, non-contact scanners or taking a multisensor approach. And because it operates the latest metrology software, including Hexagon’s PC-DMIS, it enables companies to better capture, analyse and make efficient use of metrology data.

Choose from three versions:

DEA MERCURY FX – Runway

DEA MERCURY FX – Console

DEA MERCURY FX – Top Mounted

Installation Versatility

The DEA MERCURY FX can be installed on existing steel, cast iron or granite base tables from a wide range of horizontal arm manufacturers.

Compatible with Hexagon Software and Sensors The DEA MERCURY FX is compatible with Hexagon’s tactile, non-contact sensors and multisensor systems, as well as Hexagon’s metrology software, which optimise horizontal arm performance and usage.

Robust and repeatable

The DEA MERCURY FX combines mechanical accuracy with high repeatability, a robust mechanical frame and automatic axis motion to measure even the heaviest medium, large and very large parts.

Building a world where quality drives productivity

Hexagon Manufacturing Intelligence helps industrial manufacturers develop the disruptive technologies of today and the life-changing products of tomorrow. As a leading metrology and manufacturing solution specialist, our expertise in sensing, thinking and acting – the collection, analysis and active use of measurement data – gives our customers the confidence to increase production speed and accelerate productivity while enhancing product quality.

Through a network of local service centres, production facilities and commercial operations across five continents, we are shaping smart change in manufacturing to build a world where quality drives productivity.

Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous — ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 20,000 employees in 50 countries and net sales of approximately 3.8bn EUR.

(84) 896 555 247