SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

The beverage can manufacturers encounter the task of manufacturing millions of cans daily with precise specifications. To guarantee this, batches of cans need frequent inspection to ensure measurements meet acceptable tolerances and there is minimal deviation in the dimensions of the automated tools. The measurement equipment must be rapid, precise, and consistent.

The problem that beverage can manufacturers face is producing millions of cans per day, each meeting precise specifications. To ensure quality, it is necessary to regularly inspect batches of cans to ensure that measurements such as thickness, height, and diameter fall within allowable tolerances. Additionally, it is crucial to prevent excessive deviations in the dimensions of automated tools. This is particularly important because any small changes in size can affect the packaging and transportation processes, leading to instability or product damage. Therefore, measurement equipment must ensure speed, accuracy, and repeatability to ensure that every manufactured can meets quality and safety requirements.

SOLUTION

Solartron Metrology provides precise and reliable measurement solutions for the Packaging industry. Specifically, in beverage can manufacturing inspection, we offer customized sensors and measuring devices to meet specific requirements:

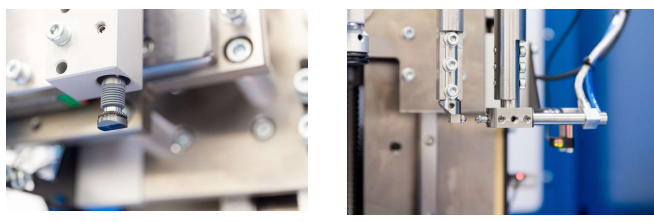

1. Height inspection sensor: A sensor is used to check the height of aluminum cans, ensuring each can meets the required dimensions.

2. Thickness inspection sensor: A second sensor is used to measure the thickness of cans, ensuring that the materials used comply with specifications and quality standards.

These solutions help optimize the beverage can manufacturing process, ensuring all products meet specific quality and size standards with the following benefits:

- High resolution: Solartron's LVDT sensors provide maximum resolution up to 0.01 micron, ideal for inspecting thin materials like aluminum can walls.

- High repeatability: With repeatability down to 0.05 micron, Solartron's LVDT sensors ensure consistent measurements even with frequent can changes.

- Ultra-compact sensors: Solartron's Mini and Flexures Single Leaf sensors are designed to fit into tight spaces, surpassing the capabilities of other sensors.

- Digital options: Solartron's Digital Orbit® network provides calibrated sensors and allows direct synchronization of readings to computers or PLCs.

- Customization: Special sensor heads, cable lengths, and other specific features can be added at our factory in the UK. With over 50 sensor types, Solartron can meet the diverse requirements of hundreds of applications.

PRODUCT

The Laser Orbit LTs can be used to scan the dimensions both above and below the lid of the can. The reading values can be easily synchronized with the Orbit system.

Standard Measurement Sensors - High Quality and Cost-Effective

Solartron Metrology's contact measurement sensors provide a cost-effective yet superior solution for precise measurement and positioning applications. With excellent load-bearing capabilities and a lifespan exceeding 100 million cycles, these sensors are ideal for a wide range of applications.

Solartron Metrology is a leading manufacturer in the field of precision measurement equipment, with over 60 years of experience and reputation in the industry. They have achieved a prominent position through their continuous commitment to improving the quality and performance of their products, providing diverse and high-quality measurement solutions for industries worldwide.

Solartron Metrology focuses on developing and manufacturing precision measurement equipment, including both contact and non-contact sensors, automated measurement systems, and control and data analysis software. Thanks to their constant innovation and commitment to quality, Solartron Metrology's products are trusted in various industries such as automotive, aerospace, medical, and electronics.

With a team of experienced experts and a commitment to customer service, Solartron Metrology not only provides top-notch measurement products but also offers professional technical support services and comprehensive consulting. Their vision is to continue contributing to the development and advancement of the measurement industry, ensuring that customers always have the support and optimal solutions for their measurement needs.

🌎🌍🌏 V-Proud is proud to be the authorized distributor of SOLATRON in Vietnam. Always ready to serve our valued customers.

☎️☎️☎️ Solution consultation: 0896 555 247

(84) 896 555 247