SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

In modern industries, especially in gear manufacturing, ensuring absolute precision not only enhances product quality but also builds brand credibility. This is where the VDI/VDE 2612/2613 standard serves as a "guiding star" for advanced gear measuring systems.

🔍 Do you know the role of the VDI/VDE 2612/2613 standard in gear inspection?

VDI/VDE 2612/2613 VDI/VDE 2612

1. What is VDI/VDE 2612/2613?

The VDI/VDE 2612/2613 standard was developed by two leading German technical organizations:

This standard defines the precision and error requirements for gear measuring machines, enabling businesses to scientifically and effectively control product quality.

Gear Testing machine

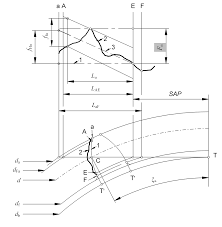

2. Accuracy Groups in VDI/VDE 2612/2613

The VDI/VDE 2612/2613 standard categorizes gear measuring machines into 4 groups, depending on precision and practical application:

3. Benefits of Applying the VDI/VDE 2612/2613 Standard

Osaka Seimitsu Gear Testing Machine

4. How to Choose the Right Measuring Machine?

When selecting a gear measuring machine, consider the following:

Some machines meeting this standard include: MarGear GMX 400 W (Mahr) and CLP-35S (Osaka Seimitsu). These modern machines are designed to meet even the most demanding requirements.

Mahr Gear Testing Machine

5. Who Should Use This Standard?

Applying the VDI/VDE 2612/2613 standard is not only a way to optimize product quality but also to elevate your business's market position. Let V-Proud help you find the optimal measuring solution for your production needs!

#VDIStandard #GearMeasurement #GlobalQuality #MarGearGMX400W #CLP35S #PrecisionMeasurement #IndustrialSolutions

(84) 896 555 247