A 3D scanner is a device that collects data about the geometry (size, shape) and sometimes the color of an object, person, or surrounding environment. The output data of a 3D scanner is a set of X, Y, Z coordinate points called a point cloud, which is used to create a complete 3D model.

Dimensional measurement is how we know and quantify the size and shape of things. It involves lengths and angles as well as geometrical properties such as flatness and straightness. Dimensional measurement is of fundamental importance for interchangeability and global trade. It is how we ensure that things will fit together. Without global length standards as the basis for standardized parts globalized industry would not be possible.

From the dawn of man, there have been leaders. Even during prehistoric time, leaders walked the earth. Unlike the dinosaurs though, leaders did not become extinct.

CMM is an acronym for the phrase: Coordinate Measuring Machine - The machine has many different names such as: 3-dimensional coordinate measuring machine, 3-dimensional measuring machine or 3D measuring machine.

1. What is CMM meter?

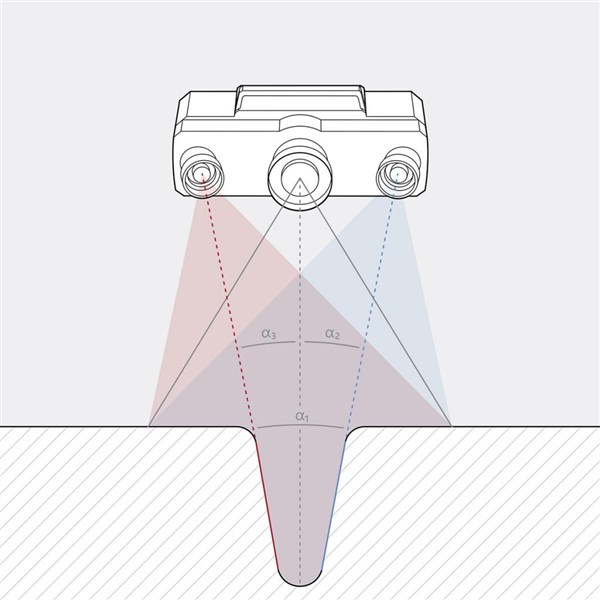

CMM is an acronym for the phrase: Coordinate Measuring Machine - The machine has many different names such as: 3-dimensional coordinate measuring machine, 3-dimensional measuring machine or 3D measuring machine. This device works based on the principle of moving the probe to touch the surface of the product to be measured to determine the coordinates of X, Y, Z points on the object. Structure of the CMM meter includes 4 main parts: Body, Measuring Head, Control System, Measuring Software. There are many types of detectors used in CMM meters: mechanical, optical detector (optical), laser detector (Laser), white light detector (White light). Depending on the model, the probe can be controlled manually or by computer. CMM meters usually determine the position of the probe in terms of displacement from a reference position in a coordinate system (X, Y, Z), in addition to moving the probe along the X, Y, axes. Z, many CMM series meters also allow the probe to be angled to reach difficult-to-reach surfaces.

.jpg)

2. Classification of several types of CMM meter

According to the structure, there are several types of CMM gauges as follows:

- The folding CMM meter: this type is usually a small, portable machine that allows the rotating head to be placed in many different directions.

Bridge-type CMM meter: There is a measuring shaft mounted vertically with a horizontal beam placed on 2 supports, this type helps to expand the measuring range of the product under test (the bridge-type CMM meter according to the X-axis).

- Spindle-type CMM tester: Measuring shaft is supported by a supporting structure.

- The staging CMM meter: There is a frame structure hanging on the supports so that the range can be extended on the objects being measured, the staging CMM meters have a structure similar to the bridge CMM.

- Horizontal axis CMM meter: The probe mounts are placed horizontally protruding, one end is attached to a vertical, movable support.

According to the control system, there are 4 types of CMM gauge as follows:

- The CMM manual measuring series: manual drive

- CMM series meters are motor driven with automatic detection process

CMM series of meters are controlled directly by computer

- CMM line of meters is linked with CAD, CAM, FMS ...

3. Application of CMM meter

CMM gauges are widely used in factories producing mechanical parts, mold making, electronics, angle, direction or depth, pattern measurement, shaping, automotive industry, rooms product research and development.

If you have any questions about the CMM meter please contact the information below, it is a pleasure to serve you:

(84) 896 555 247