SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

The D3-Inspect 300 fully automated 3D inspection solution uses structured light 3D scanning technology and is aimed at the automated quality control of high-volume production parts.

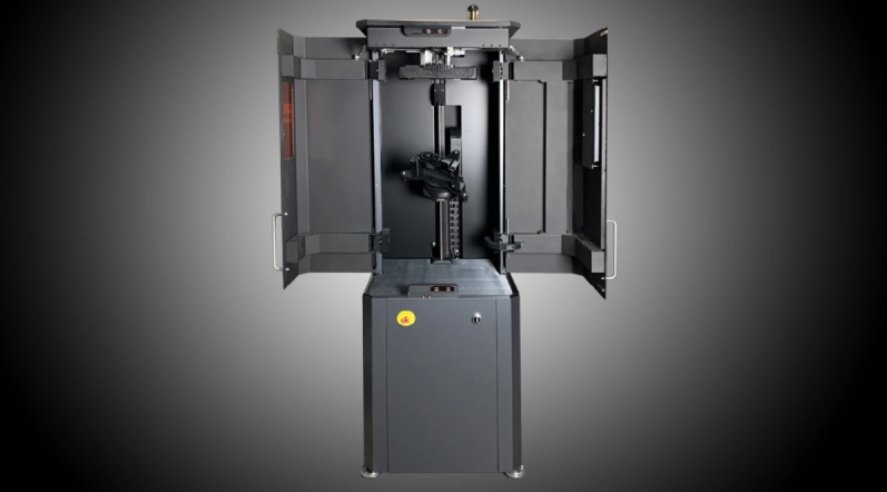

A new development for the fully automated 3D measurement of parts is launching at the Kunststoff-Institut Lüdenscheid in Germany on 14th and 15th June 2022. The D3-Inspect 300 fully automated 3D inspection solution uses structured light 3D scanning technology and is aimed at the automated quality control of high-volume production parts. The measurement system conforms according to ISO 14253 and measurement accuracy statements are according to VDI/VDE 2634 part 3. The compact scanner at the heart of the system creates a part image quickly.

The D3-Inspect has been developed as part of the ROCKET (RegiOnal Collaboration on Key Enabling Technologies) project initiative. The new measuring system was developed with project industrial partners. The objective of the project was to configure a system for quality control focused on companies producing components and assemblies who intend to monitor the production process. The paramount objective of the project was analyzing and documenting part shape and positional tolerances. Another aspect was easy operating of the device with measuring tasks manageable after a short instruction.

The D3-Inspect offers 5-axis degrees of freedom with a measuring volume of 300 x 200mm for parts weighing up to 5kg. The overall machine compact footprint is just 550 x 650 x 1900mm. The system has been built for use in production environments and requires no climatic control. Quick-change system fixtures with vacuum clamping allows measurement of multiple parts types.

The 5-axis simultaneous movements of the system rotates the part in all positions around all part features.

Automatic Measurement Evaluation

All measurement processes are fully automated and are started by an assigned QR code with further steps stored in the measurement process. Various representations of the measurement results ensure a clear understanding of the measurement ensuring action can be taken immediately based on the measured values.

Source: d3-inspect.de

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

#3D #dotudong #scanningmachine #mayquet #mayscan #productionmeasurement #sanxuat #D3inspect

(84) 896 555 247