SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

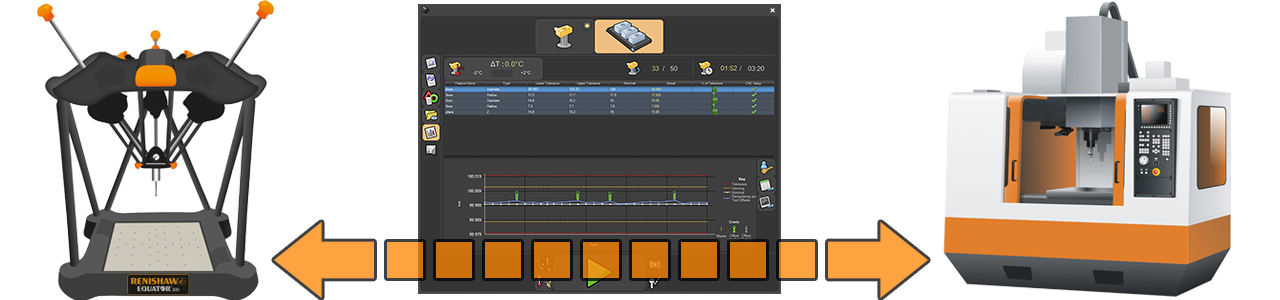

The Equator system is an innovative and flexible gauging system designed to enhance speed, repeatability, and ease of use, either manually or through automation. It's perfectly suited for shop floors and QC rooms, improving manufacturing efficiency.

Equator Gauging System – Optimized Quality Control for Modern Manufacturing

Renishaw's Equator gauging system offers advanced, flexible measurement solutions tailored for shop floors. With its exceptional accuracy, high speed, and broad applicability, the Equator system helps businesses enhance productivity while minimizing operational costs.

7 Outstanding Benefits of the Equator Gauging System in Manufacturing

1. Minimize Scrap and Enhance Product Quality

One of the biggest challenges in manufacturing is scrap caused by process errors. The Equator system addresses this by:

Performing 100% product inspection, significantly reducing undetected defects.

Providing real-time measurement data via the Process Monitor, allowing operators to make adjustments before defects occur.

Tight process control ensures improved product quality and strengthens customer trust.

2. Boost Productivity with Fast and Accurate Measurements

Traditional CMMs are often housed in temperature-controlled environments, leading to:

Space constraints for equipment.

Delays in measurement as products are transported to the CMM, sometimes pausing production or risking undetected errors.

Equator’s design allows it to operate directly on the shop floor with a faster measurement speed than traditional CMMs. Highlights include:

Short measurement cycles: Reducing the time needed to inspect each product and increasing production output.

Flexible part switching: Operators can easily switch between different measurement programs using Organiser™ software, either by selecting a button or scanning a barcode.

This minimizes waiting times and bottlenecks associated with traditional CMM inspections.

3. Seamless Automation Integration

Equator supports smart automation trends with unique integration features:

EZ-IO Toolkit: Enables easy connectivity to automated systems like robots or CNC machines.

Automatic tool offset adjustment: The optional IPC software allows automatic parameter updates to compensate for issues such as tool wear or thermal expansion.

These features save labor costs and boost manufacturing efficiency while ensuring consistent product quality.

Cost-Effective Investment with Maximum ROI

4. Low Investment Costs

Equator ensures a quick return on investment by reducing operational costs:

Replacing manual measurement: Increasing inspection speed while reducing reliance on skilled labor.

Reprogrammable capabilities: Eliminates the need for new measuring tools when product designs change, saving configuration costs.

Despite its advanced capabilities, the Equator is far more affordable than similar custom gauging solutions without compromising on accuracy.

5. Reliable Accuracy on the Shop Floor

Unlike CMMs requiring controlled environments, the Equator delivers reliable performance in shop floor conditions, operating at temperatures ranging from 5°C to 50°C and high humidity levels.

Automatic thermal compensation: Quickly compensates for temperature variations by comparing against a reference master part.

Stable operation: Reduces errors caused by thermal expansion, ensuring consistent results.

6. Simplified Training for Operators

The Equator system is user-friendly, simplifying the training process:

Easy operation: Operators can run measurement programs with a single button press or barcode scan.

Minimal expertise required: Even less experienced personnel can efficiently operate the system.

This reduces training costs and ensures uninterrupted production processes.

7. Why Choose Renishaw’s Equator Gauging System?

Equator offers unmatched versatility and value, making it a smart investment for businesses looking to optimize production, control costs, and stay competitive in the market.

With nearly 10 years of experience in delivering metrology solutions, V-Proud is proud to be the official distributor of Renishaw products in Vietnam. We guarantee genuine products with professional after-sales service.

V-Proud's experienced team is always ready to assist customers from solution consultation to installation and operator training.

Explore Renishaw’s Equator gauging system at

(84) 896 555 247