To meet the demands and overcome the difficulties in measuring paper manufacturing machinery, API provides the Radian Plus laser tracker device, enabling this measurement to realize all related metrology requirements.

The successful 3D measurement project on large offshore items in Vietnam, executed through the partnership between V-Proud (Vietnam) and Kvejborg ApS (Denmark), is more than just a successful contract. It is compelling evidence that in the era of Industry 4.0, technical standardization is the key to unlocking seamless cross-continental collaboration, delivering superior efficiency and quality to global clients.

In the dynamic context of Vietnamese industry, which is rapidly transforming and integrating deeply into the global supply chain, geometric accuracy is no longer an option but a vital requirement. Amidst this constant current, V-PROUD has positioned itself not merely as a service provider, but as an ambassador of precision, silently ensuring the quality and stable operation of key national industrial projects.

From the invention of the Laser Tracker in 1983, API Metrology has undergone 40 years of continuous innovation, pioneering in precision mechanical metrology technology. API's journey is a story of commitment to providing superior speed, reliability, and accuracy, from their machine tool calibration product lines to advanced devices that are shaping the future of the manufacturing industry.

The story of API began with a moment of inspiration in 1983 when its founder and CEO, Dr. Kam Lau, invented the Laser Tracker at the National Institute of Standards and Technology (NIST). This revolutionary invention laid the foundation for the birth of API, one of the world's pioneering companies in laser-based dimensional metrology technology.

The company's growth was fueled in December 1989 when API signed an agreement to guide Leica/Hexagon AB in manufacturing a Laser Tracker based on API's original prototype. Royalties from the initial tracker sales from 1989-1999 helped API begin its strong development. Using other designs by Dr. Lau from his time at NIST, API created the XD Laser and Ballbar, which became successful product lines for Machine Tool Calibration (MTC) and CMMs.

In 1999, API once again affirmed its spirit of innovation by launching the second-generation Laser Tracker (T2). This device was smaller, faster, and more efficient, marking a significant turning point as API began to manufacture and distribute its own products.

![]()

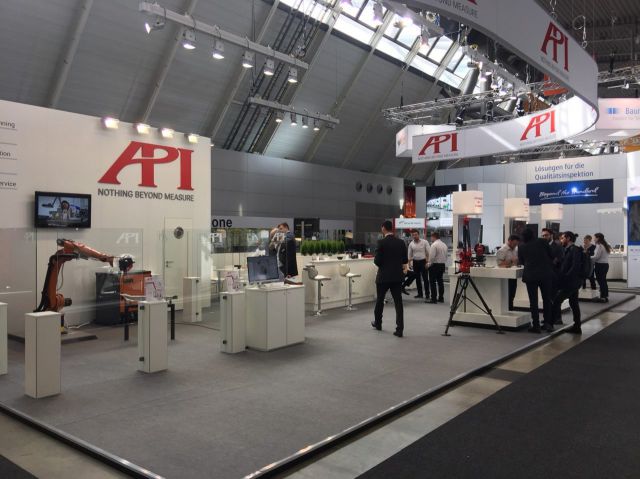

The following decade saw API's explosive growth. The company moved to its current facility in Rockville, MD, and began expanding internationally, first in Beijing in 2000, followed by Europe in 2005, France, Brazil, and India.

From Rockville, API led the next generation of trackers with the T3, OT2, and the current Radian Tracker series. They advanced tracker target technology with probes like the vProbe and automated targets like the Smart Track Sensor (STS). API is also a leader in using trackers to measure and improve robot performance with Checkbox, which includes Robot Measurement Software (RMS) and the Smart Factory Inspection System (SFIS).

In 2022, API once again pioneered the industry and technology by releasing the Dynamic 9D LADAR, a large-volume, non-contact scanning device with unprecedented speed and accuracy, set to revolutionize modern manufacturing processes for greater speed and automation.

API's vision is to be recognized by science and industry worldwide as a leading provider of advanced precision dimensional metrology solutions.

Its mission is to maintain a customer-centric business culture that supports the growth of its employees and the community. API believes that its spirit of engineering exploration strengthens its vision while meeting the increasingly demanding requirements of its customers. The company constantly strives to develop integrated measurement systems to provide operational efficiency, enhance quality, and ensure safety in automated inspection systems.

API's core values reflect this strong commitment:

Customer-Centric: Building sustainable relationships through comprehensive solutions.

Innovation and Excellence: Constantly pushing technological boundaries to set new standards.

Global yet Local: Ensuring instant and effective support for customers anywhere.

Quality and Integrity: Ensuring superior product quality and transparency in all transactions.

Comprehensive Support: Providing extended warranties, maintenance, and in-depth training.

With a legacy of innovation built since the 80s, API is not just an equipment provider but a strategic partner, helping businesses improve performance, ensure quality, and shape the future of the precision manufacturing industry.

(84) 896 555 247