To meet the demands and overcome the difficulties in measuring paper manufacturing machinery, API provides the Radian Plus laser tracker device, enabling this measurement to realize all related metrology requirements.

The successful 3D measurement project on large offshore items in Vietnam, executed through the partnership between V-Proud (Vietnam) and Kvejborg ApS (Denmark), is more than just a successful contract. It is compelling evidence that in the era of Industry 4.0, technical standardization is the key to unlocking seamless cross-continental collaboration, delivering superior efficiency and quality to global clients.

In the dynamic context of Vietnamese industry, which is rapidly transforming and integrating deeply into the global supply chain, geometric accuracy is no longer an option but a vital requirement. Amidst this constant current, V-PROUD has positioned itself not merely as a service provider, but as an ambassador of precision, silently ensuring the quality and stable operation of key national industrial projects.

In the dynamic context of Vietnamese industry, which is rapidly transforming and integrating deeply into the global supply chain, geometric accuracy is no longer an option but a vital requirement. Amidst this constant current, V-PROUD has positioned itself not merely as a service provider, but as an ambassador of precision, silently ensuring the quality and stable operation of key national industrial projects.

What sets V-PROUD apart is its serious investment in advanced metrology technology. Instead of relying solely on traditional measurement methods, the V-PROUD team brings the "power trio" of the Metrology industry:

API Laser Tracker: Specialized equipment for precisely determining the coordinates, centerlines, and planes of colossal components (from automotive plants to wind power projects) with accuracy down to the thousandth of a millimeter. This technology ensures heavy mechanical and industrial construction projects are perfectly aligned.

Measuring Arm (PCMM): Flexible and efficient for inspecting complex details, especially Jig/Fixture Welding, ensuring they strictly adhere to design standards.

Scanology 3D Scanner: Powerful in Quality Control and Reverse Engineering, allowing for the collection of dense geometric data, providing a comprehensive view of geometric deviation right on-site.

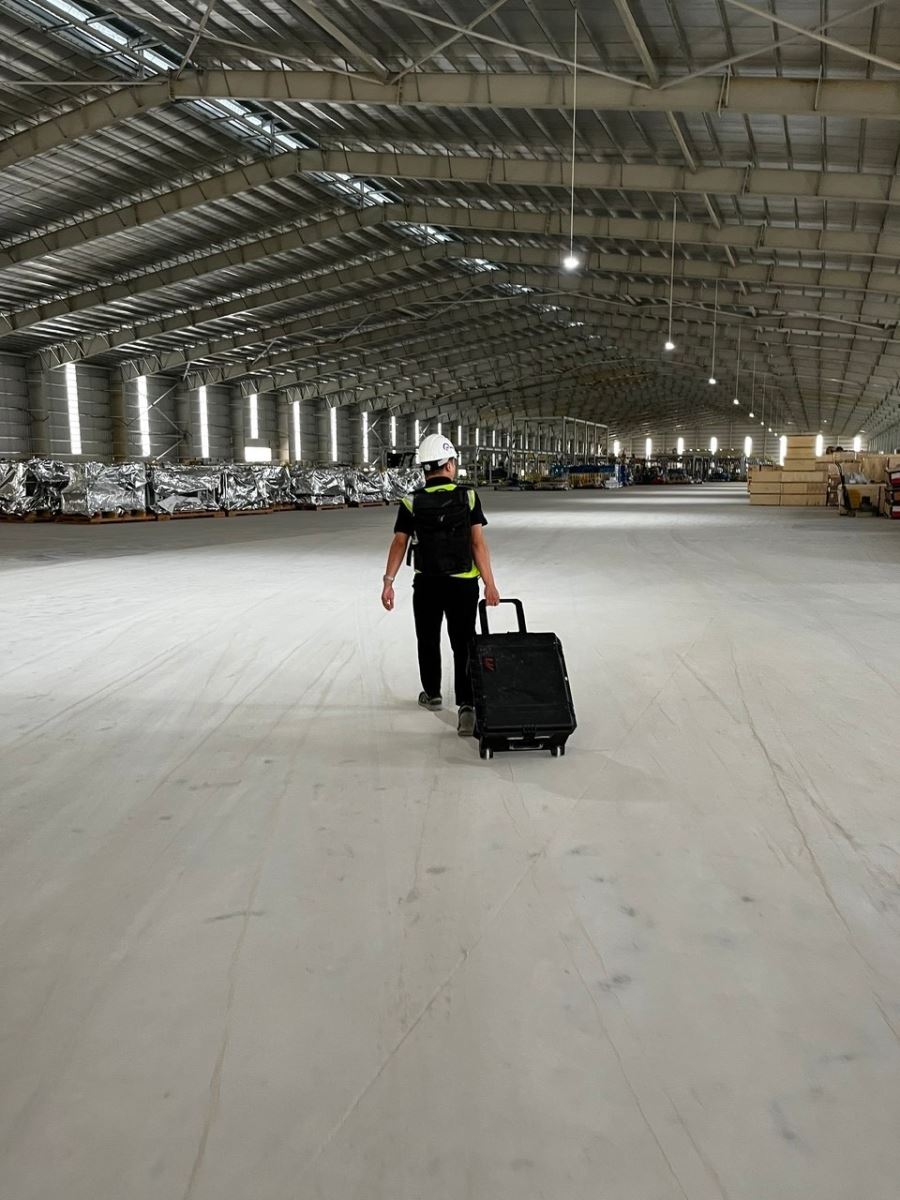

This combination of High Technology tools, operated by a dedicated and professional team, transforms V-PROUD into a Mobile Metrology Lab, ready to tackle the most complex technical challenges, from the poetic ancient capital of Huế to the sunny, windy city of Vũng Tàu.

V-PROUD’s journey is a clear testament to the perseverance of technical professionals. The wheels of the technical vehicle have rolled across regions, serving diverse sectors like Automotive (car assembly plants), Wind Power (wind energy projects), and heavy industry.

Especially noteworthy is the ability to work with and meet the stringent standards of international partners. Successful collaboration with "friends from Korea" or "brothers from Denmark"—nations that inherently prioritize technical standards—has affirmed V-PROUD's capability. Each project handover is an instance where Vietnam's metrology service is trusted and recognized by customers on an international scale, bringing pride not only to V-PROUD but also to the domestic supporting industry.

V-PROUD’s core mission goes beyond merely measuring and reporting numbers. It is about ensuring accuracy for the entire Vietnamese industry, which helps:

Stable and Safe Operation: Preventing technical risks arising from assembly or manufacturing errors.

International Compliance: Ensuring products and construction projects adhere to global technical standards, opening doors for Vietnamese products to the world.

Increased Production Efficiency: Minimizing waste and shortening installation time, thereby optimizing costs for partners like Automech, RMSYS, Soren...

On the road ahead—whether facing the challenge of reverse engineering a complex part or checking the straightness of a massive wind turbine tower—V-PROUD will remain steadfast in the spirit it has committed to: Precise – Dedicated – Professional. This spirit is the guiding principle, the promise of quality, and V-PROUD's most practical contribution to the sustainable development of the nation's industry.

If precision is the key that unlocks the door to integration and development, then V-PROUD is the locksmith holding the modern tools and practical experience to guard that door.

(84) 896 555 247