![[Workshop Highlights 23/4] Part 2: Renishaw Equator - Flexible and Precise Measurement Solution Righ]( /images/articles/2025/04/28/133903156498315165.JPG?w=400)

One of the devices that garnered significant attention from guests at the "Smart Quality Management from Production to QC" workshop was the Renishaw Equator gauging system. Thanks to its superior capabilities, this device has brought about a revolution in product quality inspection processes right within the manufacturing environment.

Read more![[Workshop Highlights 23/4]: Spotlighting impressive devices featured in the workshop! Part I: KSCAN]( /images/articles/2025/04/25/133900345472411893.jpg?w=400)

The seminar held on April 23rd in Hai Phong concluded successfully, leaving a deep impression on the attending guests. One of the devices that was the focal point of the workshop and made a strong impression on the guests was the KSCAN-MAGIC. It can be said that this is a groundbreaking solution, integrating advanced scanning technology to meet all stringent requirements in a modern manufacturing environment.

Read more

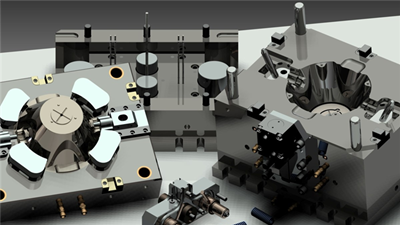

In the realm of modern manufacturing, jigs and fixtures play a pivotal role in ensuring the accuracy, repeatability, and efficiency of production processes. Traditional methods in designing and manufacturing jigs & fixtures often encounter certain challenges, including time-consuming manual measurements and the potential for errors..

Read more

🍃 All things change, and we change with them 🍃 All things change, and we change with them

Read more

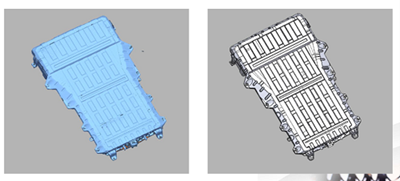

Due to its importance for safety and performance, the quality control of EV battery enclosures requires strict standards. Scantech 3D scanners have proven to be an effective and accurate tool in meeting these requirements.

Read more

The transition from ICE vehicles to EVs presents unique challenges due to the fundamental differences between the two power systems. Therefore, ensuring the high quality of battery systems is essential as manufacturers and suppliers accelerate their research, development, and engineering production for electric vehicles.

Read more(84) 896 555 247