China dominates with its ability to produce humanoid robots at a large scale, low cost, and quickly train and deploy them for practical use.

Read more

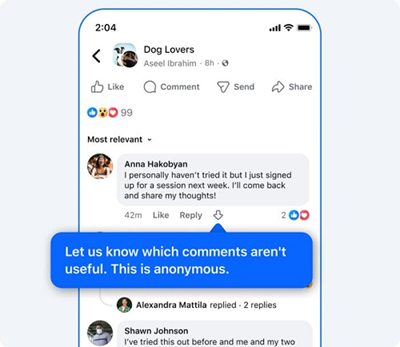

Facebook has added a Downvote button with a downward-pointing arrow in the comments section, allowing users to "downvote" unhelpful content.

Read more

Nomi, an AI assistant from Vietnamese company ADT Global, outcompeted 350 startups from 60 countries to win an award in the Supernova Pitch Competition at Gitex Asia 2025.

Read more

Switzerland has inaugurated the world's first solar power plant with panels directly installed on an active railway line.

Read more

Tokuyama Corporation (Japan) has announced plans to construct a polysilicon manufacturing plant for semiconductors in Vietnam.

Read more

The Zhiyuan Research Institute in Hangzhou, Zhejiang Province, unveiled a wearable, electric vertical take-off and landing (eVTOL) flying device on April 27th.

Read more(84) 896 555 247