SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

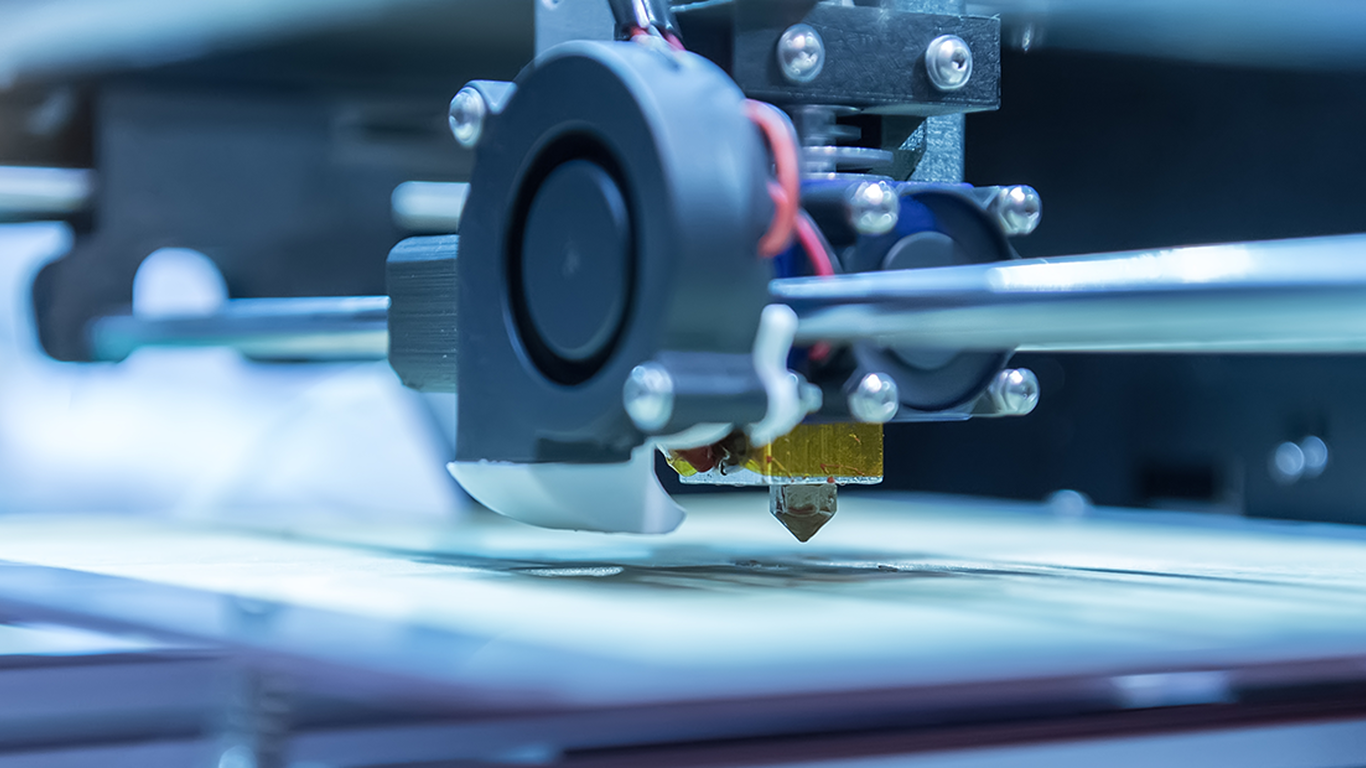

Sigma Labs has signed an agreement with AMFG to expand the footprint of both companies’ solutions and provide the marketplace with an optimized AM solution that increases quality and efficiency while decreasing the costs of serial production.

Sigma Labs, a developer of quality assurance software to the commercial 3D printing industry, has announced that it has signed an agreement with AMFG, a leading provider of manufacturing execution systems (MES) software for additive manufacturing (AM), to expand the footprint of both companies’ solutions and provide the marketplace with an optimized AM solution that increases quality and efficiency while decreasing the costs of serial production.

Specifically, the combination of the MES and in situ monitoring systems will allow AMFG and Sigma Labs users and OEM companies to:

– Automate full production workflow, including key visibility into production monitoring, with full traceability from powder to part.

– Move towards automated part and process qualification.

– View data in real-time, with ability to dive deep into analytics feed.

– Capture data to support simulation, material properties prediction and final pedigree, and key quality assurance checks to decrease post inspection needs.

– Provide data connectivity and integrity throughout the manufacturing process agnostic of equipment environment.

Jacob Brunsberg, President and COO of Sigma Labs, and Sven Hinrichs, Head of Technology Consulting at AMFG, will present details of the joint solution at the Additive Manufacturing Users Group (AMUG) conference, held in Chicago, Tuesday, April 5, 2022 at 3:00 p.m. The session is titled, Connected AM Workflow: Powder-to-Part. Sigma Labs and AMFG will discuss the criticality of actionable data insights and how to employ data in meaningful ways such as pedigree of part and material properties, final quality assurance, refining the build process. The ultimate goal is improving manufacturing OEE and ultimately shortening time to qualification for related components.

Sven Hinrichs, AMFG’s Global Head of Technical Consulting, stated, “While there are point solutions that solve specific challenges, everyone benefits when data between systems flows freely and is used to optimize the entire process. We’ve been great admirers of the tremendous strides Sigma Labs has made in ensuring part quality and qualification and are very happy to partner with their team to integrate for customers into an optimized end-to-end solution.”

According to Jacob Brunsberg, President of Sigma Labs, “We chose to partner with AMFG because of their solid reputation in the manufacturing execution space. Like Sigma Labs, AMFG is committed to deep collaboration that benefits individual customers as well as the additive manufacturing industry as a whole. The focus has shifted in the past several years from developing technology for technology’s sake, to solving the end user’s business problem. Both of our companies are industry leaders in embracing this trend.”

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

Source: sigmalabsinc

(84) 896 555 247