SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

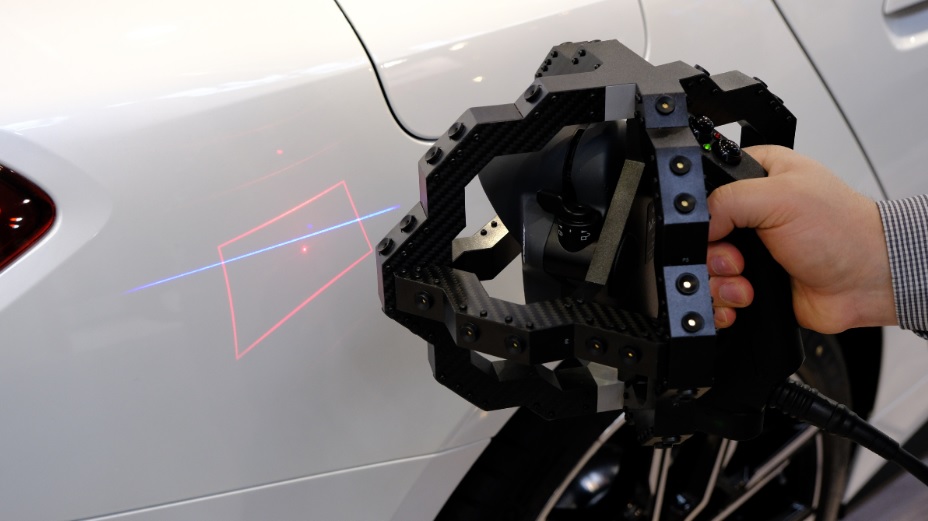

Like all Metronor products, the laser scanner M-Scan 120 does not need any stickers or targets to be placed on the part – just aim and scan.

Having made its debut at Control 2022, Metronor has released its new scanner, the M-Scan 120. This next-generation handheld 3D scanner provides a new level of scanning performance and convenience. Partnering with Nikon Metrology and having integrated their well-known technology, the new scanner combines the best of both worlds – Nikon’s experience in scanning black and white surfaces simultaneously and Metronor’s competence in tracking and navigation.

Like all Metronor products, the laser scanner M-Scan 120 does not need any stickers or targets to be placed on the part – just aim and scan. There is also no need to spray or treat measurement objects as the blue laser and sensor automatically adjusts to rapidly changing degrees of reflection with high contrast, highly absorbent coatings, almost mirrored surfaces, and almost transparent materials.

The system continues to use Metronor’s approach of bringing the measurement equipment to the part and adapting the setup to different part sizes and measurement tasks. Accurate, large-volume, target-free measurement is easy with the M-Scan 120, achieving better than 100-micron absolute accuracy over a complete car body utilizing Metronor’s brand new Multi-camera solution. The M-Scan 120 is excellent for car body prototyping and inline inspection applications.

The M-Scan 120 is highly portable, has an ergonomic handle, and is lightweight due to its carbon fiber frame weighing just1.2kg (2.65lbs).

To maximize return on investment for the customer, Metronor scanning systems also include probing capabilities using the Lightpen devices. The combined system provides the broad range of 3D measurement options making it ideal for a wide variety of measurement tasks.

Source: metronor

#laserscanner #scanner #laser #metronor #api

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

(84) 896 555 247