SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

Also in his visit, Toyota’s General Director got deeply impressed with the “Pull system” in the US supermarkets – in which, the number of goods on the shelves was always just enough and replenished immediately after customers took it away.

Toyota’s success has been recognized both in Japan and around the world. This top-leading automobile manufacturer has developed the Toyota Production System (TPS) – a system which is considered as an auto production management standard in the land of the rising sun. What is TPS? What is unique about the TPS house diagram? What are the key factors that help Toyota always ensure its products’ quality? Let’s find the answer via the following article!

Origin Of TPS

In 1950, Toyota faced a chain of difficulties in production and the newly-appointed General Director decided to find a new way out through a twelve-week survey of factories in the United States. It was interesting that after dozens of years, mass production technique in this nation barely changed. Eiji Toyoda noticed a series of issues in mass production: waste, too many products in stock, unstable organizational models and more, and these were all issues his company was coping with.

Also in his visit, Toyota’s General Director got deeply impressed with the “Pull system” in the US supermarkets – in which, the number of goods on the shelves was always just enough and replenished immediately after customers took it away. In other words, production must correspond to the quantity of goods consumed.

Eiji Toyoda at the time!

Combining with valuable lessons from Henry Ford and W. Edwards Deming, Eiji Toyoda and his colleagues came up with the Toyota Production System (TPS) – a system which focuses on the production of a smooth and continuous flow of products and tackle common issues in production as mentioned above.

TPS House Diagram

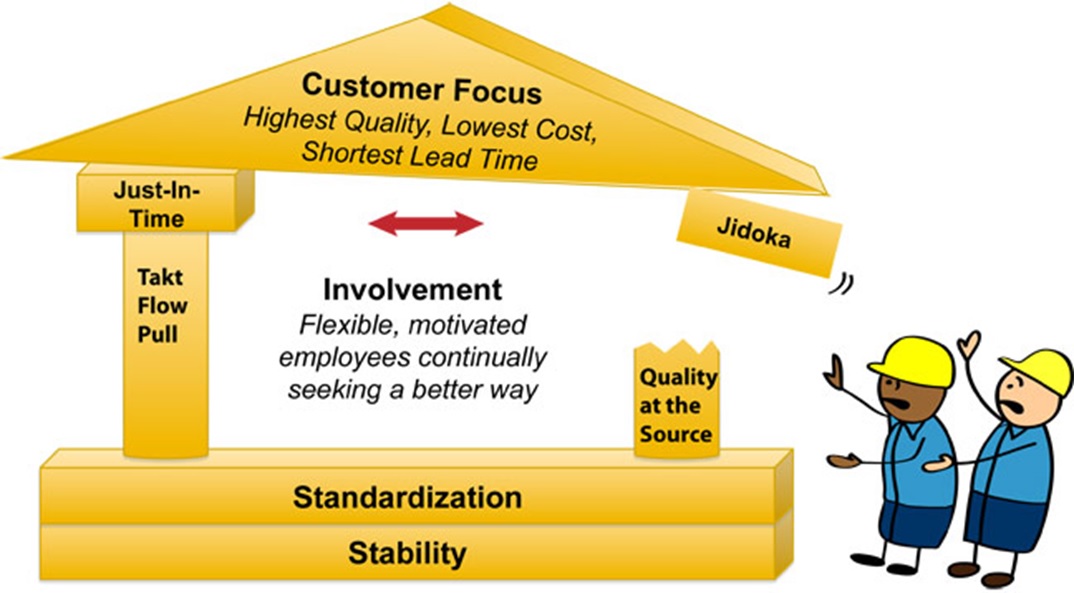

In the beginning, Toyota didn’t consider recording data on how the TPS was applied in its production facilities. However, the automobile manufacturer then realized that its supply partners also needed to comply with this unique system to achieve the best quality, save time, and reduce production costs. Fujio Cho, Toyota’s General Director at the time, built a model of the TPS house (nowadays more widely known as Lean Production) to describe the overall manufacturing philosophy and the company’s operating model.

Accordingly, the roof in the TPS house is the common and highest target all manufacturers aim at: effectively manage factors including quality, cost, time, safety, and work spirit. Two outer pillars are Just-In-Time (JIT) – mentioning just-in-time production, avoiding waste, and Jidoka (automatically checking errors) – referring to the error control process, not to allow errors to be moved to the next stage. The central elements of the TPS house are people and teamwork, continuous improvement, and waste reduction.

Follow Up On TPS Principles, Aim To Sustainable Development

There are some principles that Toyota always complies with and one of them is to continuously research and improve production to bring the best quality products and services to customers.

Customer satisfaction is the company’s long-term goal. Additionally, Toyota also focuses on redesigning the working process, creating a continuous process flow to tackle issues such as improving labor productivity, forming stable production quality, reducing inventory holding costs, and clearance.

In addition to Just-In-Time, Toyota applies the “Pull system” to deal with the overproduction often found in mass production. More precisely, this system refers to the supply of goods according to the real needs of customers, rather than mass production according to the system or schedule.

In the journey of continuous improvement, Toyota is always cautious when utilizing new technologies in its production process. It is amongst the vital factors that help the automobile manufacturer develop sustainably in the domestic and foreign markets. Before being widely adopted, these technologies are rigorously analyzed and tested. Toyota is always ready to remove some that violate its TPS principles.

Above are a few features of the TPS system of Toyota – the well-known Japanese multinational automaker. It’s not hard to see why Toyota and TPS have the ability to change the world of car manufacturing, right?!

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

(84) 896 555 247