SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

In the automotive and electronics industries, important machine components are continuing to shrink, demanding high accuracy and resolution from sensors. However, issues such as greasy surfaces or excessively high accuracy requirements can make non-contact methods insufficient.

In the automotive and electronics industries, important machine components continue to shrink, while tolerances are becoming tighter. However, checking dimensions in small areas remains necessary, requiring small sensors with high resolution and accuracy.

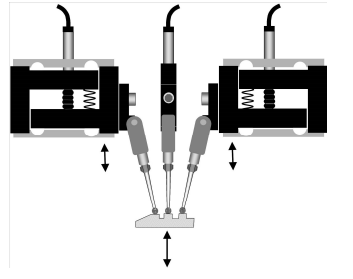

For these dimensional checks, non-contact methods may not suffice because parts may be too small or require excessively tight accuracy. Standard contact sensors may be too large or exert too much force on the sensor head.

Solatron Metrology offers a comprehensive range of slim sensors for checking multiple points in tight spaces. This includes both 6mm diameter spring-loaded and pneumatic sensors, as well as 3mm diameter measuring sensors, the world's smallest measuring sensors. A type of sensor with a wide sensitivity range of 4mm as well as lever sensors are also available for checking multiple points on small components.

With the 6mm diameter sensors, an adjustment range of up to 12mm is available with small air connections, allowing for the operation of multiple sensor heads in tight spaces.

The D6J/12/P probe is checking multiple points on a small coin.

Due to its compact size, the 3mm probe can measure small protrusions on components.

The Flexures DU/0.5/S, with a width of only 4mm and a height of 40mm, are measuring small components.

Solartron Metrology is a leading manufacturer in the field of precision measuring equipment, with over 60 years of experience and reputation in the industry. They have achieved their top position through continuous commitment to improving the quality and performance of their products, providing diverse and high-quality measuring solutions for industries worldwide.

Solartron Metrology focuses on developing and manufacturing precise measuring equipment, including contact and non-contact sensors, automated measuring systems, and data control and analysis software. Thanks to their continuous innovation and commitment to quality, Solartron Metrology's products are trusted in various industries such as automotive, aerospace, medical, and electronics.

With a team of experienced experts and a commitment to customer service, Solartron Metrology not only provides top-notch measuring products but also offers professional technical support services and comprehensive consulting. Their vision is to continue contributing to the development and progress of the measurement industry, ensuring that customers always have the support and optimal solutions for their measuring needs.

🌎🌍🌏 V-Proud is proud to be the authorized distributor of SOLATRON in Vietnam. Always ready to serve our valued customers.

☎️☎️☎️ Solution consultancy: 0896 555 247

(84) 896 555 247