The Baty R600 with its 600mm (24") screen and high specification presents the capability to make simple comparative non-contact measurement through to complex programmed measuring sequences with SPC capability and automatic edge detection.

The horizontal light beam configuration is ideally suited to large machined or turned workpieces for mounting in V blocks and centres.

There are three main readout options from Baty:

Large Screen Size: The R600 boasts a 600mm (24") screen diameter, providing ample display space for observing and measuring large or intricate details with ease.

High Precision: With advanced features and precise measurement capabilities, the R600 ensures accuracy and reliability in measurements.

Versatility: The R600 is flexible and adaptable, suitable for various industries and diverse measurement tasks, from plastic manufacturing to metalworking and electronics.

SPC Capability: With Statistical Process Control (SPC) capability, the R600 allows users to monitor and control the quality of their manufacturing processes, ensuring consistent and reliable results.

Automatic Edge Detection: The R600 features automatic edge detection functionality, enabling precise and efficient measurement of part features.

Programmable Measuring Sequences: The R600 can perform complex programmed measuring sequences, enhancing productivity and efficiency in measurement tasks.

Technical Specification

|

|

R600 |

|

X & Y Measuring range |

450mm (18") x 200mm (8") |

|

Workstage Area |

900mm (24") x 200mm (8") |

|

Screen Size |

600mm (24") - Rotating |

|

Max Work Piece Load |

50 Kg |

|

Drive Type |

Manual X, Motorised Y |

|

Image |

Erect, reversed left to right |

|

Optics/Lens Magnification |

x10, x20, x25, x50, x100 high mag condenser required for x50 and x100 |

|

Scale Resolution |

0.0005mm |

|

Accuracy |

2.5 + L/80μm |

|

Maximum Permissible Error |

2.5 + 450 (L) / 80 = 68.125 µm |

|

Light Source |

Profile 24v 150w lamp - Tugsten Halogen Surface 24v 250w lamp - Twin adjustable fibre optics |

|

Magnification Accuracy |

Profile 0.05% Surface 0.1% |

|

Helix Adjustment |

± 7° by light source alignment |

|

Options |

IES (Internal Edge Sensor) |

Lens Working Capacity - mm (inches)

|

Magnification |

X5 |

X10 |

X20 |

X25 |

X50 |

X100 |

|

Field of View |

120 (4.72) |

60 (2.36) |

30 (1.18) |

24 (0.94) |

12 (0.47) |

6 (1.72) |

|

Working Distance |

245 (9.46) |

135 (5.31) |

132 (5.19) |

106 (4.17) |

93 (3.66) |

50 (1.96) |

|

Max Work Diameter (Half Field) |

292 (9.64) |

343 (13.5) |

195 (7.75) |

|||

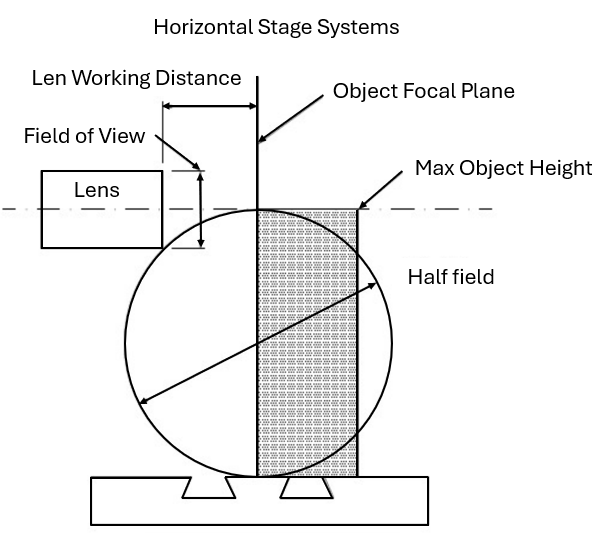

Horizontal Stage Systems

As a supplier of high quality measuring instruments to many factories and companies around the world, Bowers Group has gradually developed into a leading global brand in the field of measurement. The Group's reputation is built on continuous efforts towards perfection in all product lines being offered and many quality services to serve customers. The Group's goal is to build a sustainable reputation and continue to grow beyond customer expectations. Baty International is currently one of the brands under the Bowers Group.

Baty International began operations in 1932. From measuring products, Baty soon diversified into the field of non-contact measurement through optical profile projectors, Baty's 'Shadograph' series has been is the standard for profile projectors in the industry. These products are still manufactured at Baty's facility in Sussex, England. Video Edge Detection (VED) systems have gradually grown into the utility of profile projectors, contributing to significantly increased accuracy, repeatability and measurement speed. Acquired by Bowers Group in 2010, Baty is now an ISO 9001:2015 certified company specializing in the supply of in-house designed, developed and assembled measuring instruments.

(84) 896 555 247