This vertical light path 350mm / 14" diameter screen bench projector features a large, heavy duty high precision workstage with 250mm x 125mm measuring range and 0.5 micron resolution. Another feature is the option of a three lens turret for instant lens changes.

There are three main readout options from Baty:

The FT2-E is a Complete TOUCH SCREEN DRO with 2D Fusion touch sw for projectors with full geometric functionality and optical edge sensor. Graphical view of measured part can be printed as a fully dimensioned drawing with geometric tolerances. Other graphics include form error and SPC charts. Full reporting capability includes tabulated details with pass / fail analysis, auto link to Excel and auto sequence programming feature. SPC and best fitting to dxf (overlay). Supplied with screen mounted optical edge sensor. Integrated Mini PC running Windows 10 Pro O/S and built in 22" touch screen monitor.

The XLS is a simple two axis digital readout featuring a colour LCD display, Absolute / Incremental modes, zero reset, MM/Inch & Radius / Diameter conversion.

Vertical Bench Profile Projector XY DRO with 350mm diameter screen. Complete with SA-2510-05, 250mm x 125mm work stage with ultra smooth plain rod drives & rapid traverse on BOTH axis, 0.5 micron resolution as standard. Digital Angle Protractor & 2 'XLS' AXIS DIGITAL DISPLAY. Surface illumination included.

Vertical Bench Profile Projector 2D DRO with 340mm diameter screen. Complete with SA-2510-05, 250mm x 125mm workstage with ultra smooth plain rod drives & rapid traverse on BOTH axis, 0.5 micron resolution as standard. Digital Angle Protractor & 2 axis 'GXL' digital display with GEOMETRIC FUNCTIONS. Surface illumination.

Technical Specification

|

|

SM350 |

|

X & Y Measuring range |

250mm (10") x 125mm (5") |

|

Workstage Area |

412mm (16") x 260mm (10.5") |

|

Screen Size |

350mm (16") - Rotating |

|

Max Work Piece Load |

15 Kg |

|

Drive Type |

Manual |

|

Image |

Erect and reversed |

|

Optics/Lens Magnification |

x10, x20, x25, x50, x100 high mag condenser required for x50 and x100 |

|

Scale Resolution |

0.0005mm |

|

Accuracy |

2.5 + L/80μm |

|

Maximum Permissible Error |

2.5 + 250 (L) / 80 = 8.625 µm |

|

Light Source |

Profile 12v 100w lamp - Tugsten Halogen Surface 12v 100w lamp - Twin adjustable fibre optics |

|

Magnification Accuracy |

Profile 0.05% Surface 0.1% |

|

Helix Adjustment |

± 7° by light source alignment |

|

Options |

Rotary Turret |

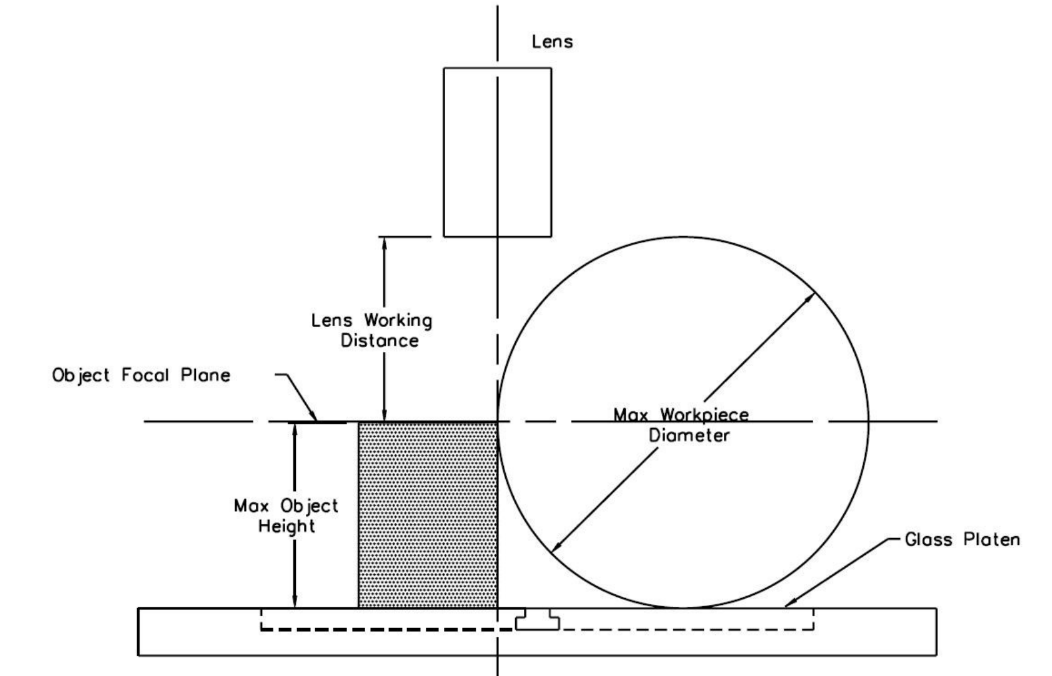

Lens Working Capacity - mm (inches)

|

Magnification |

X10 |

X20 |

X25 |

X50 |

X100 |

|

|

Field of View |

30 (1.33) |

17 (0.66) |

13.5 (0.53) |

6.8 (0.26) |

3.4 (0.13) |

|

|

Working Distance |

81 (3.19) |

38.5 (1.52) |

31 (1.22) |

14.5 (0.57) |

28 (1.10) |

|

|

Max Work Diameter (Full Field) |

170.7(6.71) |

129.9 (5.11) |

74.82 (2.94) |

37.43 (1.47) |

90.94 (3.58) |

|

|

Max Work Diameter (Half Field) |

220 (8.66) |

132 (6.38) |

52.62 (2.07) |

51.51 (2.02) |

139.9 (5.5) |

|

|

Maximum Work Piece Height |

185 (7.28) |

113 (4.44) |

106 (4.17) |

111 (4.37) |

103 (4.05) |

|

Vertical Stage Systems

As a supplier of high quality measuring instruments to many factories and companies around the world, Bowers Group has gradually developed into a leading global brand in the field of measurement. The Group's reputation is built on continuous efforts towards perfection in all product lines being offered and many quality services to serve customers. The Group's goal is to build a sustainable reputation and continue to grow beyond customer expectations. Baty International is currently one of the brands under the Bowers Group.

Baty International began operations in 1932. From measuring products, Baty soon diversified into the field of non-contact measurement through optical profile projectors, Baty's 'Shadograph' series has been is the standard for profile projectors in the industry. These products are still manufactured at Baty's facility in Sussex, England. Video Edge Detection (VED) systems have gradually grown into the utility of profile projectors, contributing to significantly increased accuracy, repeatability and measurement speed. Acquired by Bowers Group in 2010, Baty is now an ISO 9001:2015 certified company specializing in the supply of in-house designed, developed and assembled measuring instruments.

(84) 896 555 247