The MarSurf M 310 C2 product is a "brother" device to the MarSurf M 310, a portable horizontal roughness measuring instrument with the same functions as the PS 10 but offers additional, more important functions.

Dual Z-axis measurement solution for large, light and thin,and easily deformable parts. Read more below…

Explosion-proof air motor agitators provide unparalleled safety in environments prone to explosion hazards, such as laboratories and chemical plants. Utilizing compressed air instead of electricity, they ensure reliable and secure operation while offering flexibility in speed and torque adjustments, making them an ideal choice for high-risk workplaces.

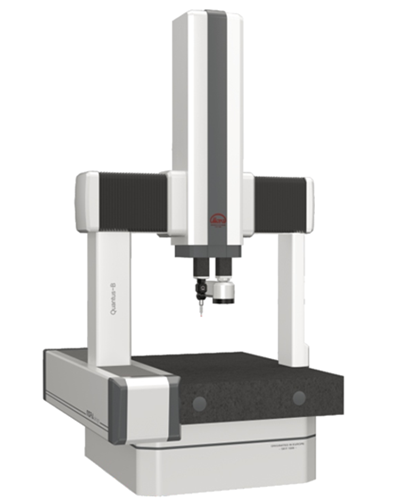

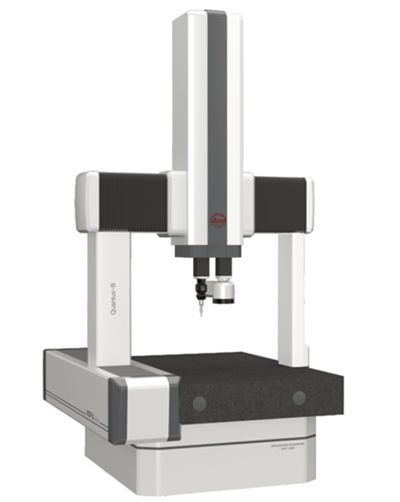

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Circulating stirrers can also be safely used for long-period temperature distribution equalization work in constant-temperature tanks.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

Dual Z-axis measurement solution for large, light and thin,and easily deformable parts. Read more below…

MarSurf VD 140 (Art. no. 6269020) The professional all-rounder for roughness and contour with 140 mm measuring path. Let's read the following article to find out more about product information:

Tribo Gear TYPE:94i-II: A Handing measuring instrument that is easy to use to measure the coefficient of static friction between objects.

Tribo Gear TYPE 34i: A Handing measuring instrument that is easy to use to measure the coefficient of static friction between objects.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

The Te Series incorporates a slip-ring type strain torque converter in the drive shaft, and displays and outputs the torque value after it has been amplified by the dynamic strain amplifier inside the control box.

(84) 896 555 247