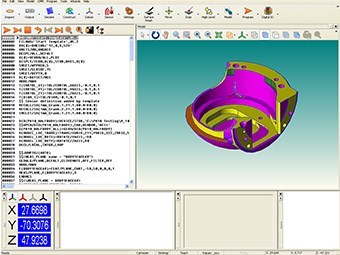

MODUS is a powerful metrology package for the Equator system, allowing CAD-driven programming and gauging of complex profiles.

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

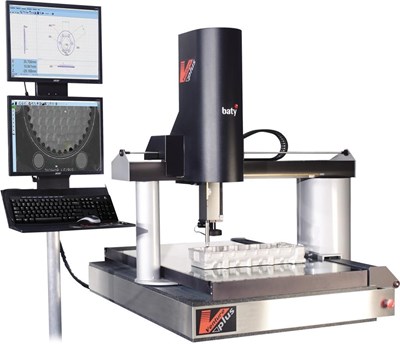

The Venture Plus range includes all of the standard Venture features with Large Measurement Volume The Venture Plus is available in four models: VP-6460-CNC with 640mm x 600mm x 250mm measuring range VP-6490-CNC with 640mm x 900mm x 250mm measuring range VP-100100-CNC with 1000mm x 1000mm x 400mm measuring range VP-100150-CNC with 1000mm x 1500mm x 400mm measuring range

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

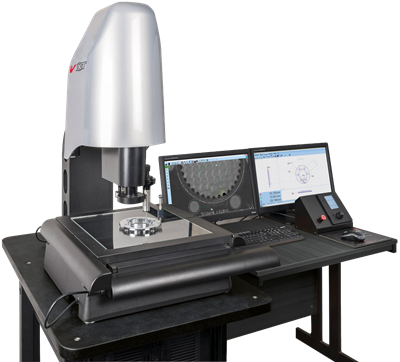

The Baty Venture 2510 CNC vision system can be used for both contact and non-contact measurement, and includes advanced features for scanning and best fitting. It is also perfect for use as a visual inspection aid because it has a powerful zoom lens and good surface illumination. A bench top CMM machine ideal for measuring small parts. Operators can easily measure geometric tolerances such as roundness and flatness Chú thích ngắn

PC-DMIS EDM Preset and Measure is both a software performing presetting tasks easily and safely, and a software accomplishing accurate and thorough quality controls on electrodes and workpieces. When installed on a GLOBAL Silver coordinate measuring machine from Hexagon Manufacturing Intelligence, PC-DMIS EDM Preset and Measure provides an extremely accurate CNC workstation for quality control, suitable for any workcell, regardless of its level of automation.

(84) 896 555 247