SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

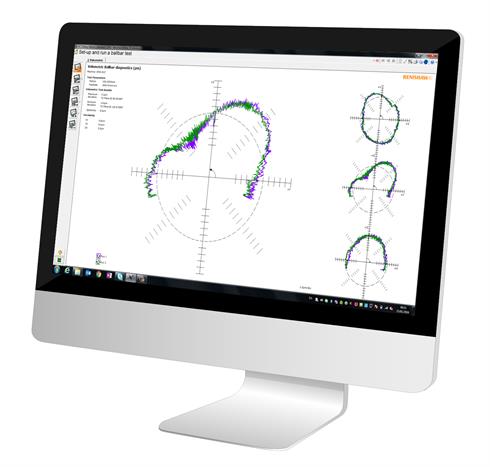

Renishaw's QC20 ballbar is highly regarded in the industry for its speed, simplicity, and effectiveness

QC20 Ballbar for Machine Tool Verification

Renishaw's QC20 ballbar is highly regarded in the industry for its speed, simplicity, and effectiveness. As a trusted solution for machine tool performance verification, it streamlines processes and ensures compliance with international quality standards. Achieving stricter tolerances, meeting customer deadlines, and maintaining high standards doesn’t have to be complex. By incorporating simple steps like machine calibration, manufacturers can enhance precision and efficiency, making the QC20 ballbar an industry-leading tool for diagnostics.

What is a Ballbar?

A ballbar is a telescoping linear sensor with precision balls at both ends. The QC20 ballbar functions as a high-precision measurement device, used to evaluate a machine tool’s performance by detecting subtle variations in the radius as it traces a programmed circular path around a fixed mount. During operation, the sensor's balls are securely located within magnetic cups, facilitating accurate radius measurements.

Why Use a Ballbar?

Defects in component dimensions or surface finishes can arise from various causes, such as:

However, many issues originate from positioning errors within the machine tool, often due to geometric, dynamic, or mechanical play-related problems.

By identifying these errors quickly—often in just a few minutes—you can implement corrective actions efficiently, regardless of whether the machine is new or used.

Understanding your machine’s true capabilities is essential for defect-free production. This knowledge allows for effective production planning and necessary adjustments. Traditionally, this involved machining test parts, followed by time-consuming inspections. This method offers limited reliability when dealing with parts of varying geometries.

With the QC20 ballbar, machine tool performance can be evaluated effectively, providing actionable insights to maintain high-quality production.

Key Benefits

Increase Output: Minimize CNC machine downtime by gaining deeper insights into its capabilities.

Reduce Costs: Produce accurate parts consistently on the first attempt, lowering scrap and inspection expenses.

Ensure Compliance: Verify that machine tool positioning meets global standards, such as ISO and ANSI/ASME.

Plan Maintenance: Create timely and effective preventative maintenance schedules with ease.

Performing a Ballbar Test

Ballbar testing is a straightforward process consisting of three main steps:

Equipped with the latest Bluetooth® Low Energy (BLE) technology, the QC20 ballbar forms a reliable wireless connection with a PC, offering enhanced power efficiency and extended battery life during use.

Explore more about ballbar testing and the range of QC20 ballbar accessories that enhance its versatility.

Ballbar 20 Software

Renishaw's powerful diagnostics software simplifies testing and reporting for preventative maintenance of machine tools. Key features include:

Comprehensive Testing and Reporting: Generates reports compliant with international standards (ISO 230-4, ANSI B5.54) or in Renishaw’s analysis format.

Selectable User Modes: Adapts to operator needs, skill levels, and authorizations, offering Quick Check, Operator, and Advanced modes.

Part Program Generator: Quickly automates the creation of ballbar test CNC part programs.

Performance History Tracking: Enables users to review machine performance variations over time with detailed graphs and plot points.

Ballbar Plot Simulator: Aids in corrective action planning or maintenance predictions based on test results.

Meeting International Standards

The QC20 ballbar is recognized as a critical component of quality assurance in manufacturing processes and as an objective assessment tool for CNC machine tools.

For ISO 10791-6 testing, the QC20 ballbar efficiently performs most required tests, capturing data to report deviations with precision using Ballbar Trace software. It is an achievable and highly effective solution for maintaining compliance with international standards.

(84) 896 555 247