SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

Handling measurement and positioning challenges on aircraft fan blades with our Digital Pneumatic Probes. Accurate and reliable, optimizing performance.

The challenge that the product must face is the spatial and positional variation of the aircraft propellers, especially in confined and restricted spaces. This variation can result in significant changes in distance and angle measurements, leading to inaccuracies, particularly at high volume levels. This poses a significant challenge in ensuring the accuracy and reliability of the measurement process, especially when high accuracy and repeatability are required.

Simultaneously, maintaining the relationship of various measurement points on complex propeller blades during the measurement process is also a considerable challenge. This variation can impact the calculation and performance of the measurement system. To address this issue, measurements must be completed as quickly as possible to minimize the potential for calculation errors due to movement during the measurement process. This requires flexibility and high accuracy from both the hardware and software of the measurement system, as well as the ability to meet the necessary speed and accuracy requirements.

The Digital Pneumatic Probes with 10mm stroke from Solartron are proposed as the ideal choice to address this challenge. They exhibit linearity across the entire displacement range and impressive resolution of <0.01 µm, making them perfectly suited for accurate measurements. By utilizing pneumatic actuation, these probes facilitate loading the blade onto the fixture with minimal moving parts. This simplification of the fixture not only enhances reliability but also leads to cost savings by minimizing errors introduced by moving components.

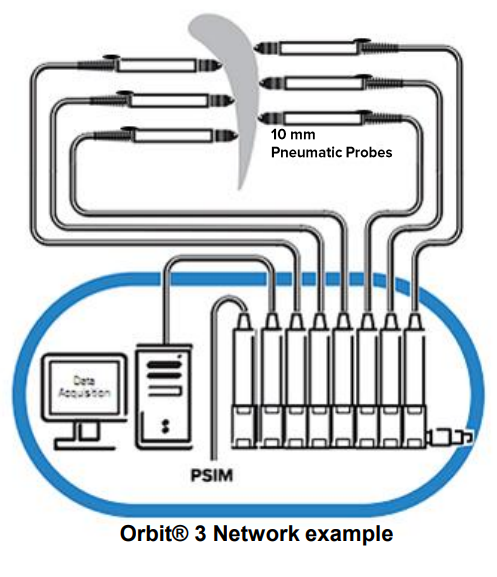

To determine the model of a complex curve, maintaining the relationship between various measurement points is crucial. Therefore, collecting all measurements in the shortest time possible to minimize the potential for calculation errors due to motion during data collection becomes extremely important. Utilizing the Orbit* 3 Network to achieve speeds of up to 4,000 readings per second per probe effectively eliminates this issue.

Additionally, rapid readings from all probes can be recorded and stored in buffer probes capable of storing up to 3,000 readings per probe. This provides a useful solution to ensure data integrity and accessibility.

The standard Digital Pneumatic Probes come with an IP65 rating to ensure long-term durability in wet or oily environments. Activation is achieved by applying pressure to the contact head.

Specifications:

- Range: From 2 to 2 mm

- Accuracy: Up to 0.05% of reading value

- Resolution: Up to 0.01 µm

- Repeatability: Up to 0.15 µm

Solartron Metrology is a leading manufacturer in the field of precision measuring equipment, with over 60 years of experience and reputation in the industry. They have achieved their top position through continuous commitment to improving the quality and performance of their products, providing diverse and high-quality measuring solutions for industries worldwide.

Solartron Metrology focuses on developing and manufacturing precise measuring equipment, including contact and non-contact sensors, automated measuring systems, and data control and analysis software. Thanks to their continuous innovation and commitment to quality, Solartron Metrology's products are trusted in various industries such as automotive, aerospace, medical, and electronics.

With a team of experienced experts and a commitment to customer service, Solartron Metrology not only provides top-notch measuring products but also offers professional technical support services and comprehensive consulting. Their vision is to continue contributing to the development and progress of the measurement industry, ensuring that customers always have the support and optimal solutions for their measuring needs.

🌎🌍🌏 V-Proud is proud to be the authorized distributor of SOLATRON in Vietnam. Always ready to serve our valued customers.

(84) 896 555 247