WHAT ARE 3D SCANNER/3D DEVICE? BASIC OPERATING PRINCIPLES

12/12/2025 358

A 3D scanner is a device that collects data about the geometry (size, shape) and sometimes the color of an object, person, or surrounding environment. The output data of a 3D scanner is a set of X, Y, Z coordinate points called a point cloud, which is used to create a complete 3D model.

I. WHAT ARE 3D SCANNER? BASIC OPERATING PRINCIPLES

WHAT IS A 3D SCANNER?

A 3D scanner is a device that collects data about the geometry (size, shape) and sometimes the color of an object, person, or surrounding environment. The output data of a 3D scanner is a set of X, Y, Z coordinate points called a point cloud, which is used to create a complete 3D model.

PRINCIPLES OF DATA COLLECTION BY 3D SCANNER

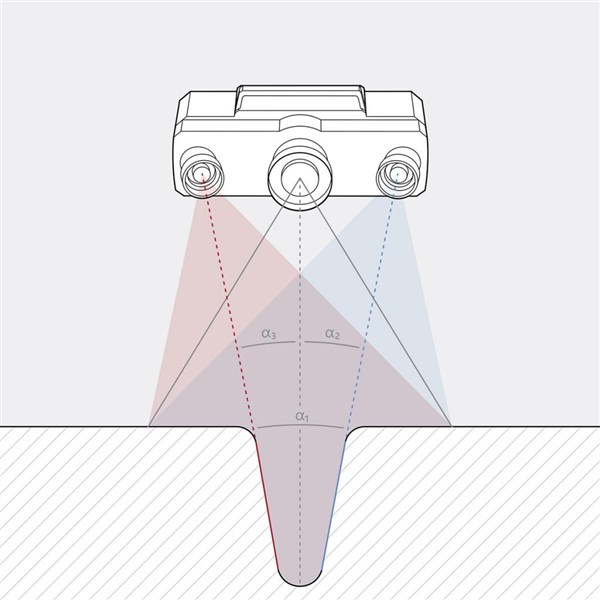

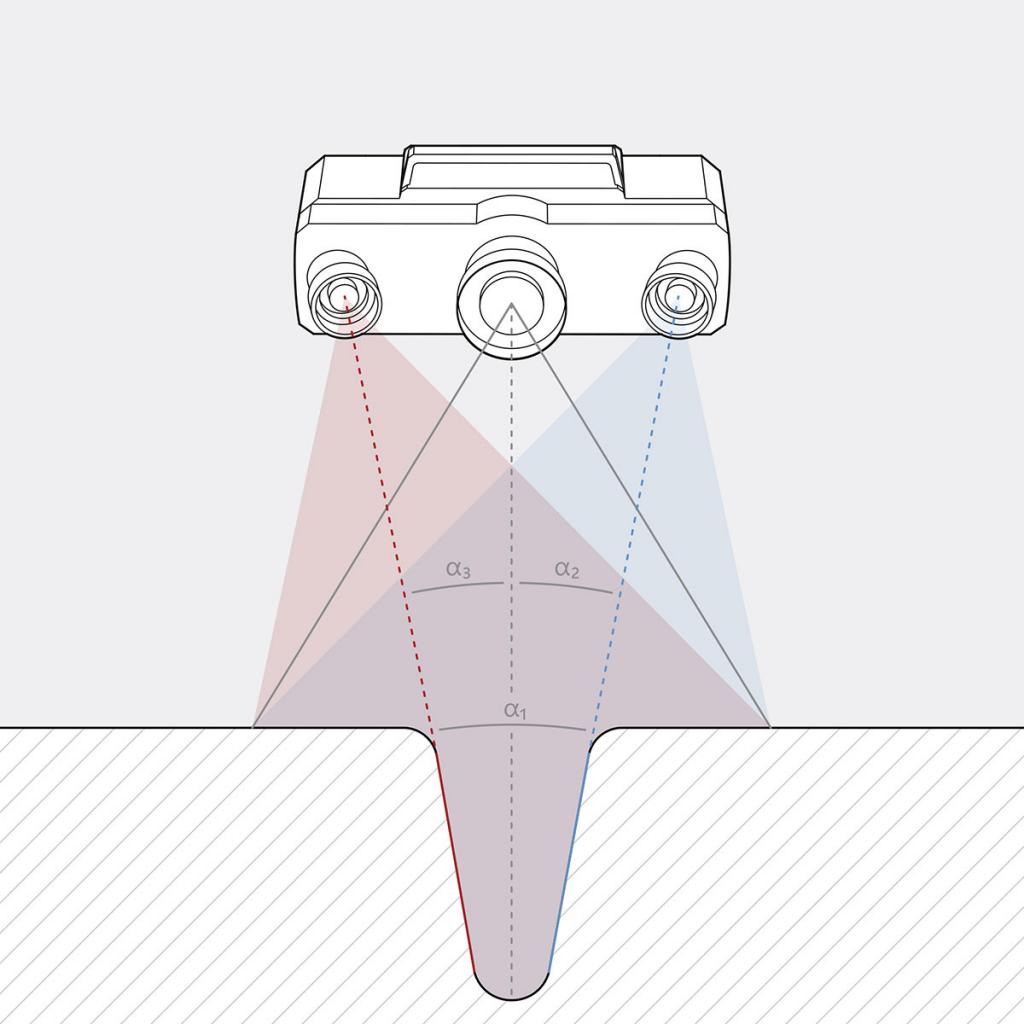

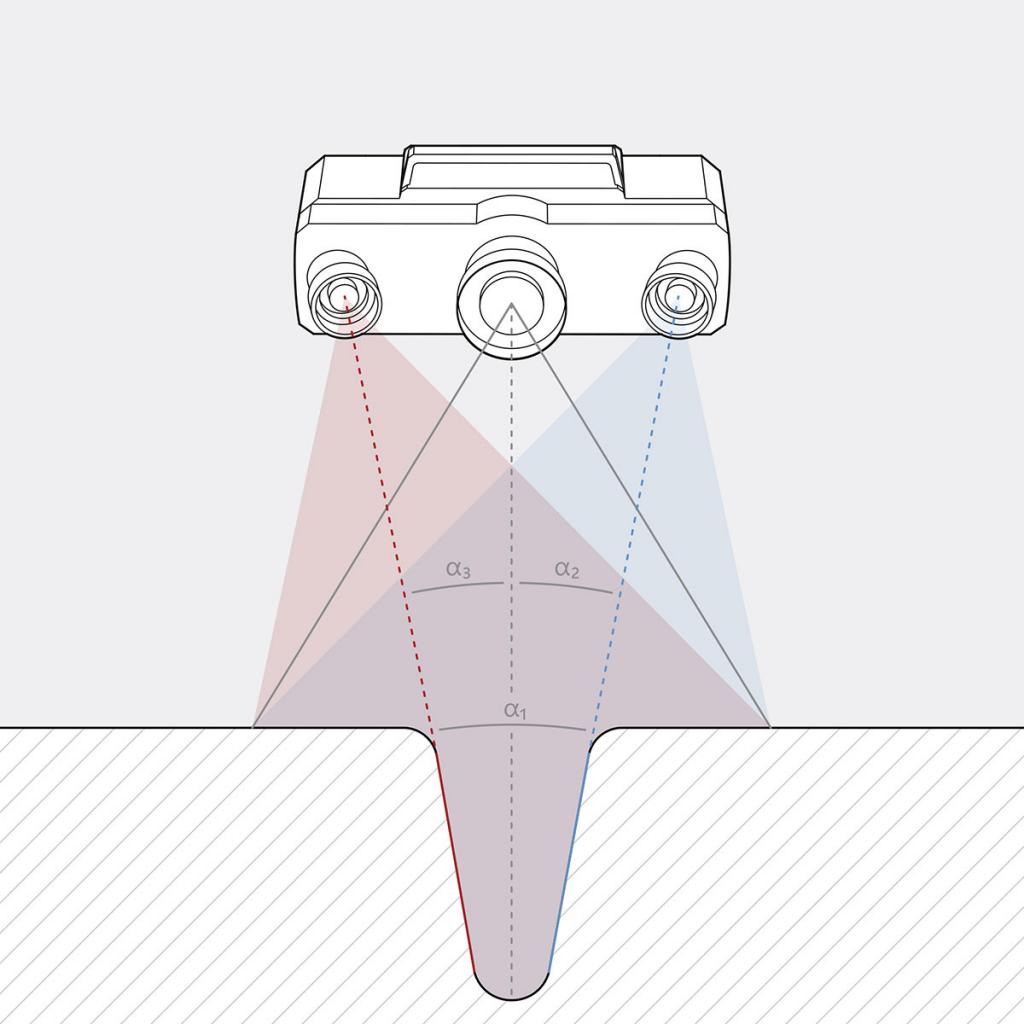

The most common principle of professional 3D scanners is Optical Triangulation. The 3D scanner projects a light source (laser or structured light) onto the object. Then, one or more sensors (cameras) observe the position of this light source. By knowing the projection angle, the viewing angle, and the distance between the light source and the sensor, a 3D scanner can accurately calculate the 3D coordinates of millions of points on a surface.

II. ANALYSIS OF 4 TYPES OF SPECIALIZED 3D SCANNER

Currently, there are 4 main types of 3D scanners on the market, classified based on technology and application purpose.

1. BLUE LASER 3D SCANNER

- Basic operating principle of a 3D scanner

- Operating principle of a blue laser 3D scanner

- This is a professional handheld 3D scanner, designed for applications requiring high accuracy in industrial environments.

- Key features: Uses a blue laser beam. The short wavelength of the green laser reduces scattering, allowing 3D scanners to collect data with superior resolution and accuracy, especially on dark, glossy, or metallic surfaces.

- Typical examples: 3D scanners such as NimbleTrack, K-Scan, and SimScan E often use green laser technology in combination with optical tracking systems to ensure overall accuracy.

- Core applications:

- Precision mechanics/Measurement: Quality control (QC) of parts, comparison with CAD drawings, and reverse engineering of machine parts.

- Accuracy: Very high, typically reaching 0.02 - 0.05mm.

Note: Often limited in working range without an accompanying tracking system, and the output is always dense Point Cloud data. Green laser 3D scanners are the top choice for high detail.

2. RED LASER 3D SCANNER AND LASER TRACKER SYSTEM

- In this classification, a Laser Tracker is a measurement system that uses a red laser to measure 3D coordinates, often categorized as a 3D scanner (or 3D measurement system) for large objects.

- Key Features: Uses a red laser to track and measure long distances with absolute accuracy. This system does not create a dense point cloud immediately but is primarily used to measure the 3D coordinates of target points (SMR) or laser scan lines.

- Typical Example: API Laser Tracker.

- Core Applications:

- Large-scale Industry: Measurement and assembly of oversized components such as aircraft fuselages, turbine blades, or large industrial structures.

- Long-Distance Measurement: Ability to accurately measure over long distances (tens of meters). Laser Tracker 3D scanners provide high accuracy for extremely large objects.

3. ELECTRONIC TOTAL STATIONS AND LIDAR TECHNOLOGY

- Electronic total stations and 3D LiDAR (Light Detection and Ranging) scanners are specialized devices for digitizing space, environment, and civil engineering structures.

- Key features: They typically use the Time-of-Flight (ToF) principle, emitting millions of laser pulses per second to measure distances and create point clouds. Total stations are traditional surveying tools that measure selective points, while LiDAR is a 3D scanning technology that creates point clouds of entire areas.

- Core applications:

- Architecture, Construction, Surveying: Topographic surveying, railway tracks, mapping existing structures, monitoring structural deformation.

- Graphics and GIS: Creating realistic 3D models of large areas.

4. STRUCTURED LIGHT 3D SCANNER

- Structured light 3D scanners are a versatile scanning solution, balancing speed, color detail, and moderate accuracy.

- Key Features: Instead of using lasers, this 3D scanner projects geometric patterns (structured light) onto the object. The camera captures the distortion of the light pattern to calculate the 3D shape.

- Typical Examples: 3D scanners such as the 3Devok MT or MQ.

- Core Applications:

- Medical and Entertainment: Scanning faces, human bodies, or medical components. Creating detailed 3D models for the game industry and visual effects (VFX).

- Painting/Conservation: Digitizing artworks and artifacts to collect high-quality color (texture) data.

- 3D Printing: Creating 3D printed models quickly.

- The fastest scanning speed is the biggest advantage, as it collects data from the entire surface in a single illumination.