SCANOLOGY has just introduced NimbleTrack Gen2. With upgraded technology, SCANOLOGY's NimbleTrack Gen2 is capable of scanning large and complex areas significantly faster, while maintaining measurement-level accuracy. This is the next generation of the company's mobile optical tracking and 3D scanning systems. SCANOLOGY's NimbleTrack Gen2 is designed to deliver higher performance, especially in speed and measurement range.

A breakthrough opportunity for R&D processes awaits the Vietnamese engineering community. The specialized workshop "Driving Engineering Innovation Through Smart Simulation" organized by ANSYS will take place on October 29, 2025, at the Innovation Hub Building, updating the latest advanced simulation solutions for the manufacturing, electronics design, and Nano-Micro industries.

In the global race to automate manufacturing, China is emerging as a pioneer with the “dark factory” model – where robots and artificial intelligence completely replace humans. Requiring no light or rest, the new generation of factories operate continuously 24/7 with superior precision and efficiency.

Whether for global manufacturers or small custom shops, API’s measurement expertise, combined with advanced metrology equipment, can execute fast and convenient reverse engineering projects.

REVERSE ENGINEERING

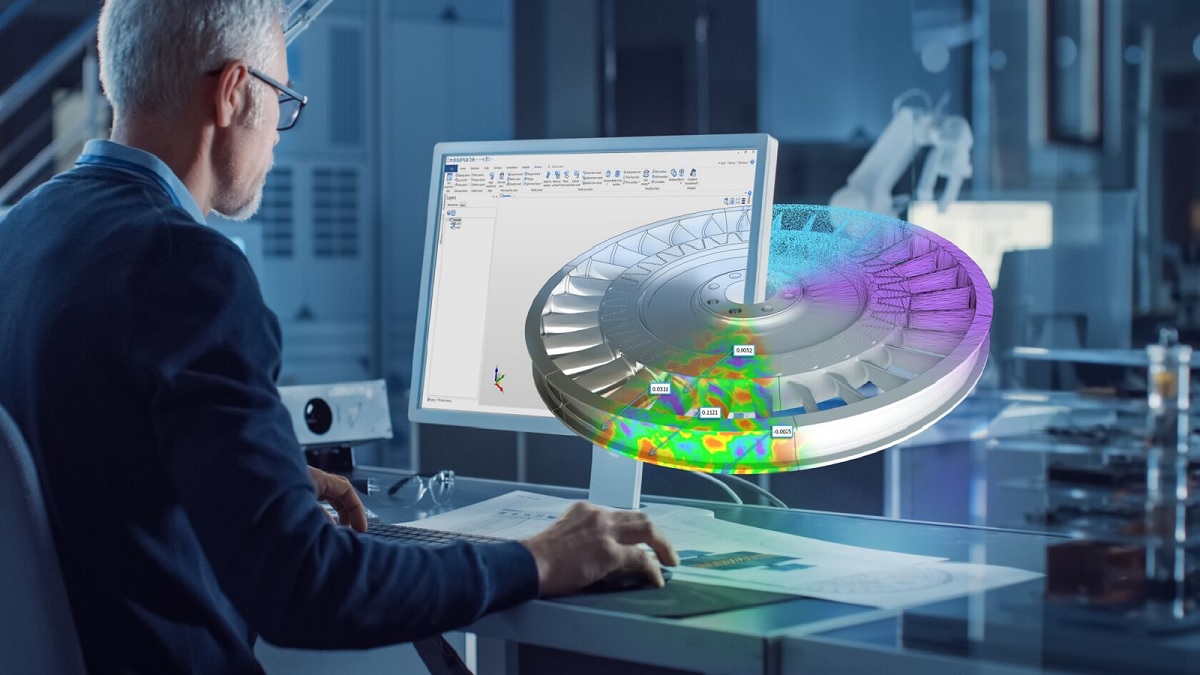

API metrology’s Reverse engineering services include scanning as-built parts to the creation of a 3D digital point cloud and CAD Model.

Whether for global manufacturers or small custom shops, API’s measurement expertise, combined with advanced metrology equipment, can execute fast and convenient reverse engineering projects. API’s Laser scanning services can create data from an existing part or compare captured data to a CAD model.

API reverse engineering service utilizes advanced software and equipment. On their own facility or yours. API has perfected an efficient reverse engineering and modelling process. With them, you can review your reverse engineering project with the experts and latest technology.

3D MODELING

Utilizing reverse-engineering software, API technicians can extract optimal CAD entities including curves, surfaces, and prismatic features from the generated polygonal models of reverse-engineered digitized parts providing a professional part CAD modeling solution. Typical applications include prototype parts, legacy part replication, product benchmarking and historical documentation.

LASER SCANNING

Whether your requirement is designing a part within existing part constraints or a CAD model of a prototype part, API’s laser scanning services can provide a digital point cloud of your part. We can laser scan your parts at our facility or attend your location with our equipment if your part is large or of a highly sensitive nature. API utilizes a range of non-contact scanners for both large and intricate parts providing the necessary detail and accuracy for your project.

CAD COMPARE

API technicians can provide a coloured topographical 3D report showing quantified deviations in the scanned model which can be presented in free form or with reference alignment conditions. Geometry extraction with actual versus nominal reporting. API technology is able to take the ‘as-generated’ point cloud and directly compare it against a nominal CAD model of the scanned part.

API’S OTHER SERVICES INCLUDE:

Read Quality Mastery magazine to get more information about quality management: https://qualitymastery.v-proud.vn/

If you are looking for quality management solutions, visit the following websites: v-proud.vn/product and doluongcongnghiep.vn.

(84) 896 555 247