The RUP1 (Ultrasonic Probe) module is one of the most unique accessories of the Renishaw REVO 5-axis system. It allows the CMM to perform material thickness measurements using ultrasonic waves. With the Renishaw REVO 5-axis RUP1, you can measure the thickness of walls without needing to approach from both sides. This is an extremely useful solution for the aerospace industry, where the Renishaw REVO 5-axis is used to inspect hollow turbine blades.

In the aerospace industry, where accuracy and efficiency are vital, optimizing the measurement process is key to maintaining a competitive edge. Meyer Tool, a leading manufacturer of aerospace engine components in Cincinnati, Ohio, found a breakthrough solution with Renishaw’s Equator™ comparison measurement system. This solution not only effectively replaces traditional rigid measurement equipment, but also delivers significant cost and productivity benefits.

The Equator–X™ 500 is a groundbreaking measurement system from Renishaw, specifically designed to provide the latest advanced measurement solutions for on-the-floor process control. With its ability to operate as two systems in one, this device offers a flexible and effective solution for manufacturers.

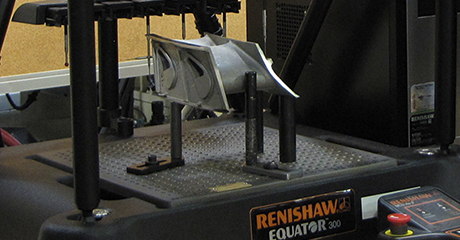

In the aerospace industry, where accuracy and efficiency are vital, optimizing the measurement process is key to maintaining a competitive edge. Meyer Tool, a leading manufacturer of aerospace engine components in Cincinnati, Ohio, found a breakthrough solution with Renishaw’s Equator™ comparison measurement system. This solution not only effectively replaces traditional rigid measurement equipment, but also delivers significant cost and productivity benefits.

Challenge: Reliance on Expensive and Inflexible Hard Gauges

The manufacturing of aerospace engine components requires extremely high precision, often checked with specialized hard gauges. According to Beau Easton, Quality Manager at Meyer Tool, the company owns more than 100 hard gauges, each costing between $10,000 and $20,000. This cost does not include maintenance and reconfiguration costs, which can be as high as $3,000 to $10,000 for any change in part design. Reliance on hard gauges not only increases the initial investment cost, but also creates a major barrier to manufacturing flexibility, especially when contracts require frequent design changes.

The Solution: Equator™ - Breakthrough Gauge Technology

Meyer Tool found the answer with Equator™, a breakthrough measuring system. Equator™ works based on comparative gauging, using a master part that has been precisely calibrated by a CMM to “baseline” the system. Measurements are then compared to this master part, ensuring high repeatability, with errors below ±2 µm, even in production environments with fluctuating temperatures.

Cost-effective replacement: In the testing phase alone, one Equator™ system replaced at least four rigid gages on a production line. This saves Meyer Tool significant costs in the design, manufacture and maintenance of dedicated gages.

Maximum flexibility: Unlike rigid gages that are only used for one type of part, one Equator™ can support the measurement of many different types of parts. Reprogramming to measure new parts takes just minutes, eliminating the need for expensive and bulky rigid measuring equipment.

GD&T Measurement: Combined with MODUS™ software and the SP25M scanning probe, the Equator™ is capable of measuring complex features such as true position (GD&T), diameter, profile, and roughness with tight tolerances of ±0.001 to ±0.003 inches.

Superior Efficiency: Optimize Performance and Quality

The Equator™ is designed to operate efficiently on-site. Rapid re-mastering, equivalent to the time it takes to measure a single part, allows the system to adapt to temperature changes without interrupting production.

- Increased Productivity: Measuring time per part is only 2 to 6 minutes, fully meeting the TAKT time of lean production lines. This shortens production cycles and increases productivity.

- Real-time quality control: Equator™ is seamlessly integrated with the Orion Statistical Process Control (SPC) system, providing real-time measurement data and SPC charts. Operators can easily track process deviation trends, and make timely adjustments to CNC machines to reduce scrap and optimize product quality.

- Increased first-time yield: Thanks to 100% part inspection and tight control of the production process, Meyer Tool achieved an impressive first-time yield of 98.9% in January 2011, with virtually zero defects.

Towards the future of smart manufacturing

The adoption of Equator™ has established Meyer Tool as a leader in manufacturing process innovation. The benefits are not only savings on initial investment costs but also significant improvements in productivity and product quality, thereby enhancing reputation and competitiveness in the market.

The Equator™ system has proven to be a flexible, efficient and economical measurement solution, suitable for all production environments. This is not only an investment in equipment but also an investment in long-term competitiveness.

Contact us now to experience Equator™!

V-PROUD JOINT STOCK COMPANY

Address: Lot A-23 Xuan Phuong Garden, Xuan Phuong Ward, Hanoi, Vietnam.

Hotline: 0896 665 247

Email: xinchao@v-proud.vn

(84) 896 555 247