Dual Z-axis measurement solution for large, light and thin,and easily deformable parts. Read more below…

Surface evaluations using skidless tracing are needed not only in the measuring room but more and more in the production area. And MarSurf M 410 is the perfect device to do this task.

THE MOST ACCURATE KREON MEASURING ARM The Kreon Onyx measuring arm is the epitome of high performance. It guarantees 3D measurements of parts and tools with an unprecedented level of accuracy

Established in 1941 and headquartered in Renens, Switzerland, TESA manufactures and markets precision measuring instruments that stand for quality, reliability and longevity.

The I++ Simulator option is a stand-alone software package for the simulation of the complete measuring process. Realistic and comprehensive collision monitoring can only be carried out by visualising the complete process (machine, sensor, tool changers, tools, fixture and part).

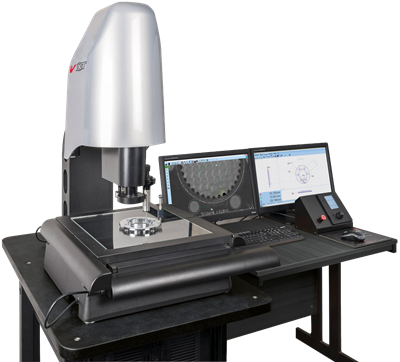

The Baty Venture XT 3030 CNC vision system can be used for both contact and non-contact measurement, and includes advanced features for scanning and best fitting. It is also perfect for use as a visual inspection aid because it has a powerful zoom lens and good surface illumination. A bench top CMM machine ideal for measuring small parts. Operators can easily measure geometric tolerances such as roundness and flatness

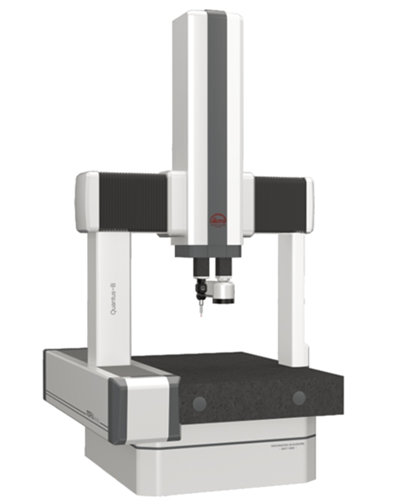

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

(84) 896 555 247