The I++ Simulator option is a stand-alone software package for the simulation of the complete measuring process. Realistic and comprehensive collision monitoring can only be carried out by visualising the complete process (machine, sensor, tool changers, tools, fixture and part).

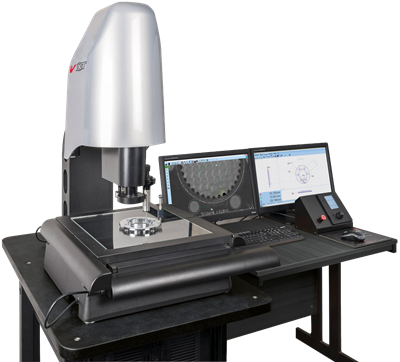

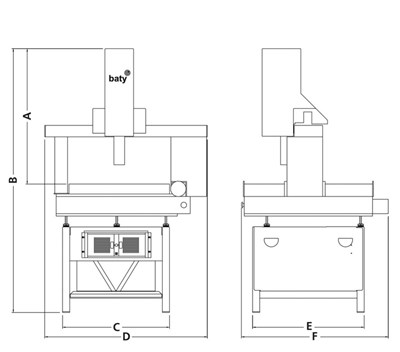

The Baty Venture XT 3030 CNC vision system can be used for both contact and non-contact measurement, and includes advanced features for scanning and best fitting. It is also perfect for use as a visual inspection aid because it has a powerful zoom lens and good surface illumination. A bench top CMM machine ideal for measuring small parts. Operators can easily measure geometric tolerances such as roundness and flatness

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

The Baty Vision System Venture Plus range includes all of the standard Venture features with a little more... measuring range, that is. Large Measurement Volume The Venture Plus is available in four models: VP-6460 with 640mm x 600mm x 250mm measuring range VP-6490 with 640mm x 900mm x 250mm measuring range VP-101040 with 1000mm x 1000mm x 400mm measuring range VP-101540 with 1000mm x 1500mm x 400mm measuring range

Primus bridge CMM is a CMM with multiple patents launched to the market by MORA Germany which has accumulated a century of technical strength and rigorous manufacturing technology. Read more below…

Laser Triangulation Sensor from Solartron: Accurate and non-contact measurement for metal and reflective surfaces

The Baty R600 with its 600mm (24") screen and high specification presents the capability to make simple comparative non-contact measurement through to complex programmed measuring sequences with SPC capability and automatic edge detection.

(84) 896 555 247