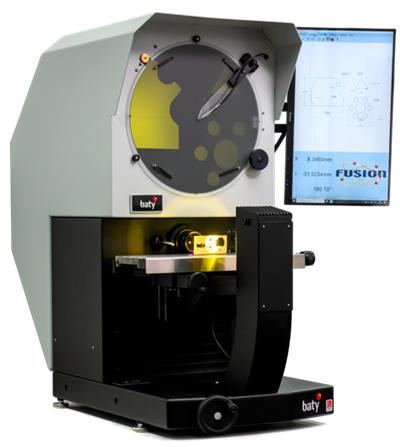

The Baty R400 bench mounted profile projector with its 400mm screen combines high accuracy non-contact measurement and inspection with a large 300mm x 150mm measuring range.

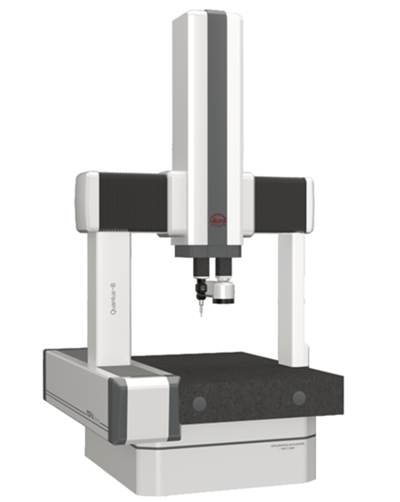

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

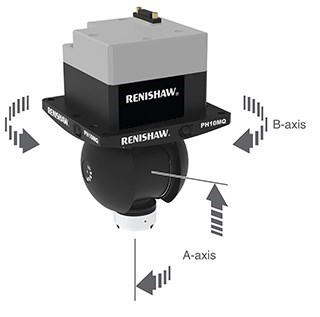

The range of PH10 PLUS heads increase throughput by giving automated CMMs the added capability of program controlled probe re-orientation.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

SIMSCAN 22 by SCANTECH is not just a 3D scanning device, but a symbol of refinement and exceptional performance, ready to elevate quality standards in any production and inspection process.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

Primus HS-422/ MGH 422 - Ultra high precision, small parts measurement solution. Read more below…

Dual Z-axis measurement solution for large, light and thin,and easily deformable parts. Read more below…

The Baty SM20 is a vertical light path floor standing profile projector with a 500mm / 20” screen. The Baty SM20 features a large heavy duty high precision work stage with 250mm x 125mm measuring range and a 0.5 micron resolution.

The MarSurf M 310 with printer is a Mahr’s new product line, has the same functions as the PS 10, but offers additional, more important functions. Let’s learn about the product through the article below.

(84) 896 555 247