The TrackScan P-550 is an advanced optical 3D scanning system by SCANTECH, unlock the future of industrial-grade 3D scanning with the TrackScan-P550, offering unmatched precision, marker-free technology, and multi-scenario adaptability.

The SIMSCAN-E is an intelligent, wireless, and palm-sized 3D scanner that combines a lightweight design with exceptional performance. Featuring advanced edge computing and wireless data transfer, it sets a new standard for flexible, wireless with high precision and accuracy3D scanning.

The ergonomic and mobile CMM Workstation offers the flexibility and workspace optimisation required on the production floor and metrology lab.

Primus bridge CMM is a CMM with multiple patents launched to the market by MORA Germany which has accumulated a century of technical strength and rigorous manufacturing technology. Read more below…

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

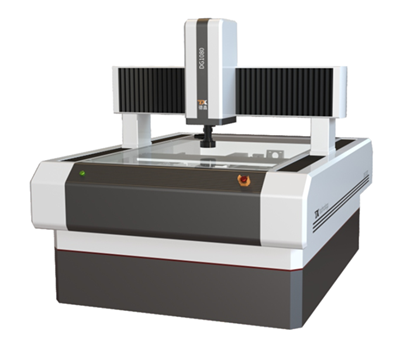

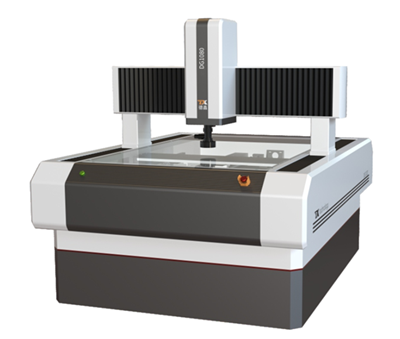

DG Series Gantry Optical Measuring Machine, which suitable for large part and batch inspection. Read more below…

Sensor Probe Head Renishaw Module TP20 - SF Low Force Compact module changing touch-trigger probe, which allows the use of a range of stylus configurations and extensions to access features on complex parts TP20 with MCR20 and PI 200-3 The TP20 is a compact 5-way, or 6-way, kinematic touch-trigger probe system. The two-piece design, comprising probe body and detachable stylus module(s), connected using a highly repeatable magnetic kinematic coupling.

Primus bridge CMM is a CMM with multiple patents launched to the market by MORA Germany which has accumulated a century of technical strength and rigorous manufacturing technology. Read more below…

DG Series Gantry Optical Measuring Machine, which suitable for large part and batch inspection. Read more below…

(84) 896 555 247