The MarSurf M 310 with printer is a Mahr’s new product line, has the same functions as the PS 10, but offers additional, more important functions. Let’s learn about the product through the article below.

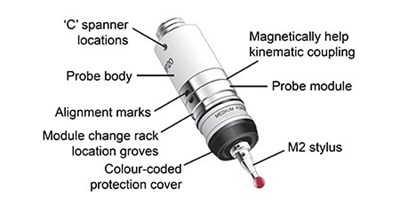

Compact module changing touch-trigger probe, which allows the use of a range of stylus configurations and extensions to access features on complex parts

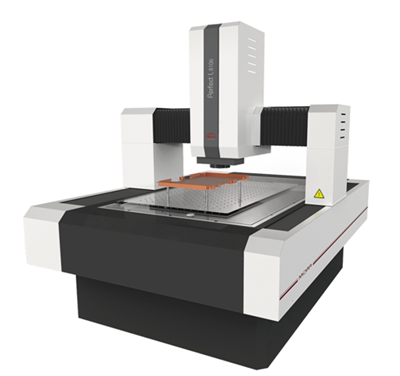

Air bearing measurement solution for large, light and thin,and easily deformable parts. Read more below…

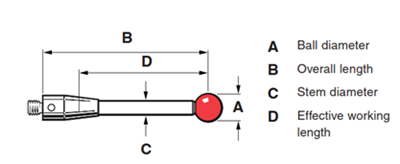

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

Primus bridge CMM is a CMM with multiple patents launched to the market by MORA Germany which has accumulated a century of technical strength and rigorous manufacturing technology. Read more below…

QUINDOS is the most powerful analysis tool for many types of coordinate measuring devices and differing applications, mainly in power plant, automotive, aircraft and machine tool powertrain industries. The database structure contains all of the measurement data, making it available for further processing and reporting. A host of very special functions improves the efficiency of measuring process.

I/O Flow Manager is the complete integration solution for installing coordinate measuring machines (CMMs) into a production cell. The all-in-one hardware and software package enables manufacturers to integrate quality assurance directly into production with minimal pre-programming or operator training.

(84) 896 555 247