In principle, styli are the co-ordinate measuring machine’s (CMM’s) “tools”, providing the same relationship that turning tools have with lathes, and milling and boring tools have with milling machines. When measuring with a touch-trigger probe, the machine uses the stylus to take the data points on the surface of the workpiece. Each touch generates a point that is defined using co-ordinate values in X, Y and Z. Feature, size, form and position can then be computed from these points.

Primus HS-422/ MGH 422 - Ultra high precision, small parts measurement solution. Read more below…

Dual Z-axis measurement solution for large, light and thin,and easily deformable parts. Read more below…

The Baty SM20 is a vertical light path floor standing profile projector with a 500mm / 20” screen. The Baty SM20 features a large heavy duty high precision work stage with 250mm x 125mm measuring range and a 0.5 micron resolution.

The MarSurf M 310 with printer is a Mahr’s new product line, has the same functions as the PS 10, but offers additional, more important functions. Let’s learn about the product through the article below.

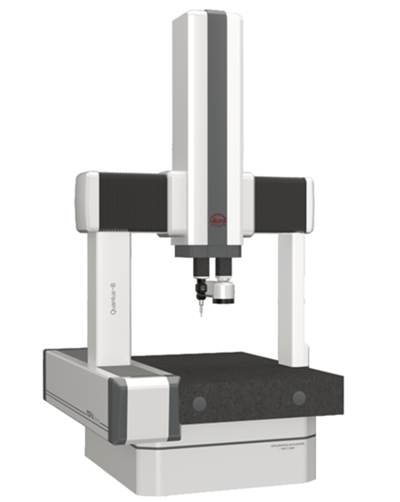

Our bridge type measuring machine Primus L presents a compact and stable machine concept. Read more below…

The days when using SPC was optional, when it was something that might be worth investigating someday are long gone. Today, any company that wants to be competitive knows that SPC is the most useful processes control tool available.

Primus bridge CMM is a CMM with multiple patents launched to the market by MORA Germany which has accumulated a century of technical strength and rigorous manufacturing technology. Read more below…

iReal M Series Color 3D Scanner (M stands for Master) is a brand-new professional 3D scanner series launched by SCANTECH. Update product information through the following article.

300mm screen vertical light path projector with multi-function readout unit and printer. Robust design with full geometric measuring functionality ideal for the shop floor.

(84) 896 555 247