Bạn đang cần giải pháp đột phá để tối ưu hóa quy trình sản xuất và phát triển sản phẩm? Dịch vụ Scan 3D chuyên nghiệp của V-Proud chính là chìa khóa!

Dịch vụ đo lường di động bằng LaserTracker, Scan 3D, đo jig/fixture ô tô tại hiện trường. Chính xác, nhanh chóng, tiết kiệm chi phí cho sản phẩm khổ lớn và siêu lớn.

Bạn đang tìm kiếm một phương pháp đo lường chính xác cho các chi tiết cơ khí nhỏ, linh kiện điện tử, khuôn mẫu, hoặc các sản phẩm có hình dạng phức tạp? Dịch vụ đo profile khổ nhỏ trên máy đo 3D CMM Baty chính là giải pháp tối ưu dành cho bạn! Hãy cùng tìm hiểu về giải pháp đo lường chính xác, nhanh chóng và tiết kiệm này qua bài viết dưới đây:

In the automotive industry, precision is extremely important. The manufacturing process involves many complex assemblies, and even the smallest deviations can lead to major performance, safety and quality problems. That's why Fixtures/Jig measurement and inspection services are so important. Let's learn about the measurement and accuracy testing service of Fixture/Gig in the article below:

Why Is Measuring and Testing a Fixture/Jig Important?

Fixtures/Jig are essential tools used in the production and assembly of automobile parts. They ensure that parts stay in place during machining, welding or assembly. Precision fixtures ensure that each part is produced consistently and meets the demanding precision requirements of the automotive industry. However, over time, jigs can wear out or become misaligned, leading to manufacturing errors.

V-PROUD Fixture/Jig Measurement and Inspection Service:

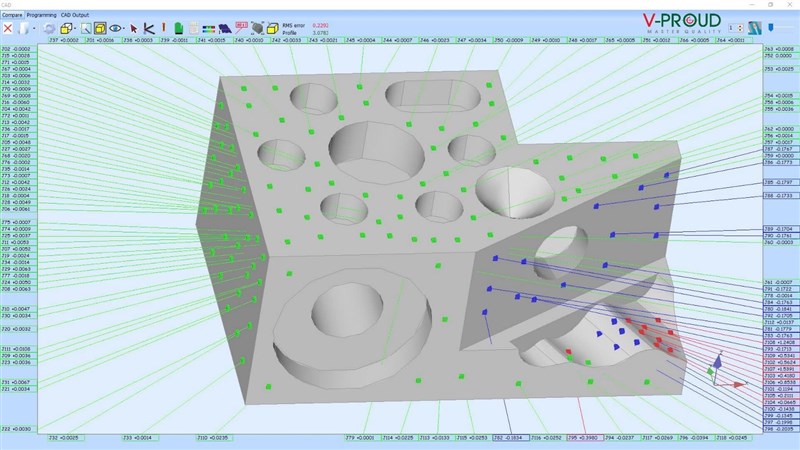

1. Accurate Measurement: V-Proud uses the most advanced measurement equipment, including API tracker, Arm, and 3D Scanner mobile CMMs, to provide extremely precise measurements of your jig. These tools allow detection of even the smallest deviations from original specifications.

.png)

2. Fixtures Calibration: Periodic adjustment of fixtures is necessary to maintain production line accuracy. V-Proud's technical team will provide customers with accurate data to calibrate fixtures to the highest standards in the industry, ensuring they always operate optimally.

3. Inspection and Verification: We provide comprehensive inspection services to verify that your fixtures are in perfect condition. This includes visual inspection, dimensional inspection and functional testing. Our goal is to identify and fix any problems before they affect your production process.

.png)

4. Reporting and Documentation: After each measurement and inspection, V-proud engineering will provide detailed reports on the condition of the fixture, including any deviations and recommended corrective actions. This documentation is important for maintaining quality control and for customer reviews.

.png)

5. Custom Solutions: Every manufacturing process is unique, and so is your jig. Therefore, V-Proud offers measurement and inspection services customized to your specific needs, ensuring that your fixtures are perfectly suited to your production requirements.

Why Choose Us?

By cooperating and using V-Proud's services, customers can ensure that your fixtures are always in the best condition, reduce the risk of manufacturing errors, improve product quality, and ultimately save money, time and cost.

PLEASE CONTACT US NOW TO RECEIVE CONSULTATION AND SHARE DETAILS ABOUT FIXTURES/JIG/JIG MEASUREMENT AND INSPECTION SERVICES.

********************************************

![]() V-PROUD JOINT STOCK COMPANY

V-PROUD JOINT STOCK COMPANY

![]() Address: Lot A-23 Xuan Phuong Garden, Phuong Canh Ward, Nam Tu Liem District, Hanoi

Address: Lot A-23 Xuan Phuong Garden, Phuong Canh Ward, Nam Tu Liem District, Hanoi

![]() Hotline: 0896 665 247

Hotline: 0896 665 247

![]() Email: xinchao@v-proud.vn

Email: xinchao@v-proud.vn

(84) 896 555 247