Công ty Cổ phần V-Proud là đơn vị tiên phong tại Việt Nam trong lĩnh vực cung cấp giải pháp đo lường cơ khí chính xác và quản lý chất lượng toàn diện cho các nhà máy sản xuất công nghiệp. Thành lập từ năm 2015, V-Proud tự hào là đối tác chiến lược của hơn 12 thương hiệu đo lường hàng đầu thế giới, đồng hành cùng các tập đoàn lớn như VINFAST, SAMSUNG, FOXCONN, và nhiều doanh nghiệp khác tại Việt Nam.

Với triết lý kinh doanh "Uy tín x Giá trị x Bán hàng = Lợi nhuận," V-Proud không ngừng đổi mới, mang đến các giải pháp tiên tiến giúp nhà máy làm chủ chất lượng, tối ưu hóa hiệu quả sản xuất và nâng cao vị thế cạnh tranh.

Chúng tôi cam kết mang lại giá trị vượt trội thông qua việc cung cấp thiết bị hiện đại, tích hợp công nghệ tiên tiến, đào tạo đội ngũ chuyên sâu và đồng hành cùng sự phát triển bền vững của khách hàng.

Hãy để V-Proud trở thành đối tác đáng tin cậy của bạn trên hành trình xây dựng hệ thống sản xuất chất lượng và bền vững!

Đọc thêm

Nếu như đo điểm (TTP) chỉ cung cấp tọa độ rời rạc, thì quét liên tục mang lại lượng dữ liệu khổng lồ để đánh giá hình dạng (form) của chi tiết. SP25M của Renishaw là đầu đo quét nhỏ nhất thế giới (đường kính 25mm), tích hợp cả hai chức năng: Quét biên dạng và đo điểm chạm trong cùng một hệ thống

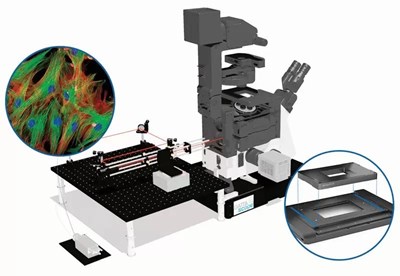

Đọc thêmTrong các lĩnh vực khoa học đời sống, phân tích hóa dược hay khoa học vật liệu hiện đại, độ phân giải quang học và nội dung thông tin của các phương pháp hiển vi cổ điển đã không còn đủ đáp ứng. Để có được thông tin toàn diện nhất về một mẫu vật, các hệ thống kính hiển vi độ phân giải cao. Do việc định vị mẫu năng động và chính xác cực cao là yếu tố không thể thiếu trong hầu hết các lĩnh vực ứng dụng, các bàn quét dựa trên piezo là một giải pháp tối ưu.

Đọc thêmTrong thế giới sản xuất hiện đại, sự đánh đổi giữa tốc độ và độ chính xác là "kẻ thù" của lợi nhuận. Thấu hiểu điều đó, V-Proud phối hợp cùng Renishaw mang đến giải pháp nâng cấp toàn diện cho hệ thống đo lường của bạn.

Đọc thêm(84) 896 555 247